SOFTWARE

Control software development environments

Both kits contain all the needed tools for the rapid prototyping of power converter control techniques, including simulation, code generation, debugging, and testing.

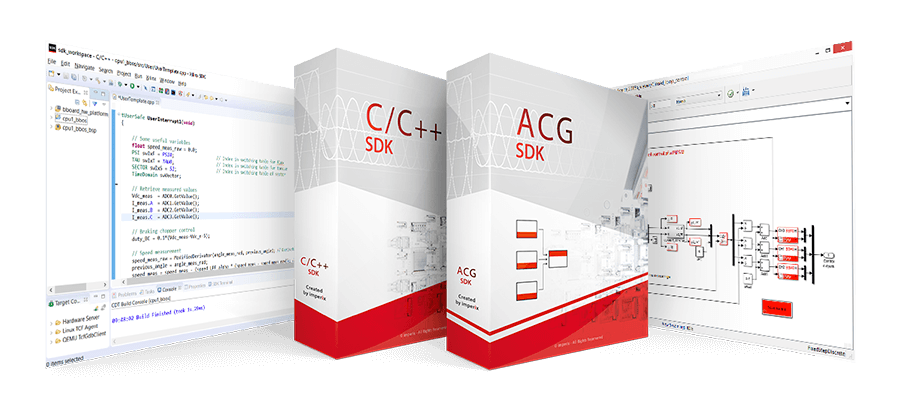

Various environments are supported, ranging from C/C++ coding to Matlab Simulink and Plexim PLECS.

Control software development made easy

With our control software development environments, numerous of these side tasks are alleviated, allowing engineers to focus on what really matters, namely the design and validation of the power converter control algorithms.

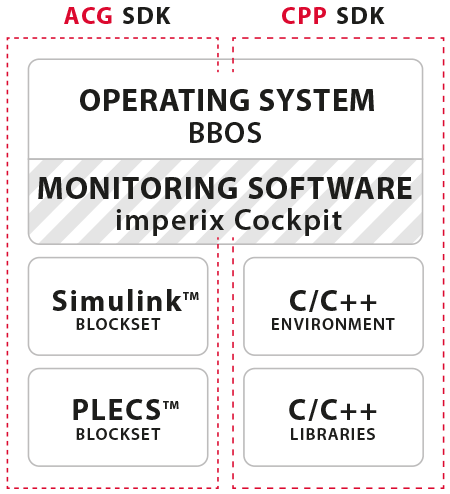

Software Development Kits (SDKs)

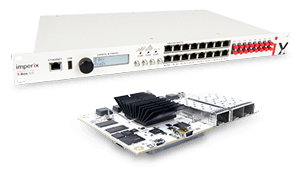

Imperix offers two distinct sets of tools for embedded control software development: ACG-SDK and CPP-SDK. In addition, both SDKs also support editing the FPGA-based firmware.

Accelerate developments

Whether you prefer working from your usual simulation software or writing C/C++ code, our controllers can be programmed in just one click.

Overall, we observe that most users are able to get first satisfying experimental results after just a tens of hours in the lab.

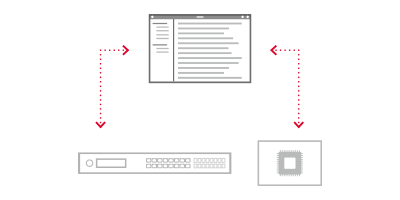

Work on multiple hardware

With imperix’s solutions, the same control implementation can be used on any programmable controller.

This results in a complete portability of your code and significant savings in time and developments efforts.

Leverage an open framework

Unlike many development tools, our software allows you to implement, modify, tweak or test anything that comes to your mind.

What’s more, you can even customize the FPGA firmware. This can be particularly useful for demanding or complex applications.

software development kits (SDK)

The two kits apply to all imperix programmable converter controllers. They contain the necessary tools to support the quick and easy development of embedded real-time control software for power electronic systems. This ranges from the development environments themselves, to simulation models, compilers, supporting libraries, as well as debugging tools.

Imperix’s control software development kits support the implementation of all sorts of closed-loop control algorithms for virtually any power converter topology.

| FEATURE | ACG SDK | CPP SDK |

|---|---|---|

| Simulation and code generation from Simulink * | ||

| Simulation and code generation from PLECS ** | ||

| C/C++ code development environment | ||

| BBOS operating system | ||

| Imperix Cockpit monitoring software | ||

| User-editable area inside the FPGA (Kintex 7) | ||

| Stacked operation (B-Box RCP or B-Board PRO only) |

** Requires a valid PLECS license issued by Plexim GmbH (either Standalone or Blockset) as well as a PLECS Coder license.

Volume pricing

When multiple licenses are related to the same customer, degressive pricing applies, according to the overall purchase history. The table below shows the proposed volume discounts:

Volume discounts

| 2nd | 41% | 6th | 57% |

| 3rd | 49% | 7th | 59% |

| 4th | 53% | 8th | 60% |

| 5th | 55% | 9th | 61% |

PRODUCTION LICENSES

All controllers can be flashed up to 20 times with this free-of-charge license. This authorizes firmware upgrades during the entire system lifetime in production environments.

Licensing policy

R&D LICENSES

These licenses allow unlimited access to the controllers. All software licenses are:

- Target-locked (i.e. tied to the controller unit)

- Lifetime (no renewal fees, free software updates)

- Usable on an unlimited number of computers

In multi-controllers configurations (B-Box RCP or B-Board PRO only), only the master unit must be licensed. The master is the controller hosting the user-defined CPU program.

PRODUCTION LICENSES

All controllers can be flashed up to 20 times with these free-of-charge licenses. This authorizes firmware upgrades during the entire system lifetime in production environments.

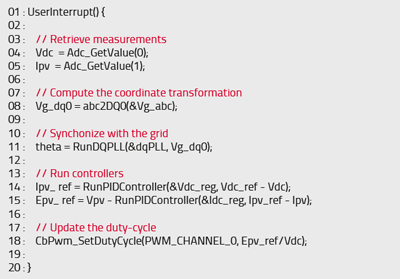

C/C++ CODE DEVELOPMENT

for conventional converter control implementation

For teaching applications, learning how to write code for embedded control also reveals to be an important aspect of any power electronic courses.

- Superior performance

Implementing closed-loop converter control using C/C++ code generally offers superior performance over the graphical control design and automated code generation.

- Improved flexibility

With hand-written control software, there are virtually no limitations to what can be implemented.

- Teaching

C/C++ programming offers a convenient way to either learn, understand or teach about the constraints of hard real-time systems.

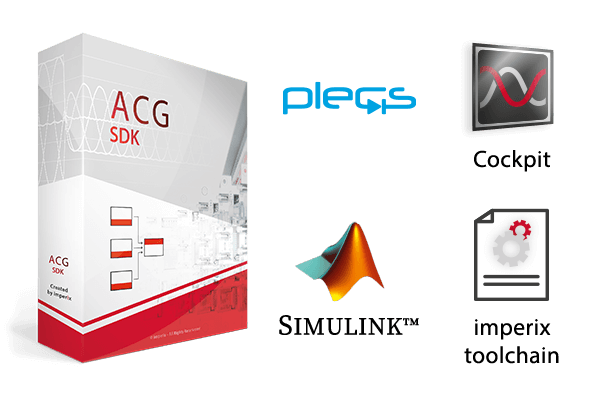

AUTOMATED CODE GENERATION

for graphical converter programming and maintenance

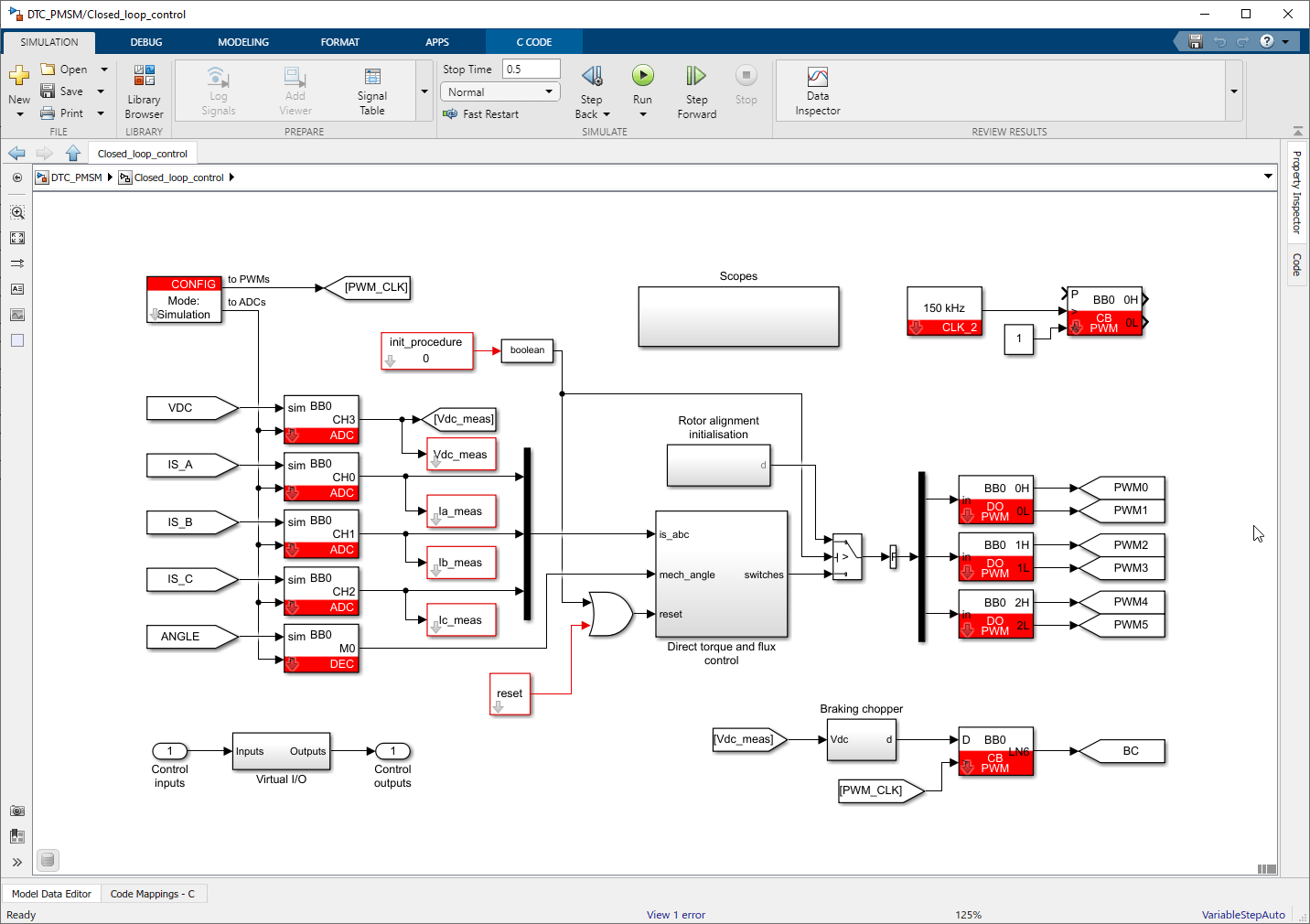

In addition to the C/C++ control implementation approach, the development of run-time control algorithms can be implemented thanks to automated code generation.

With the blocksets for Simulink and PLECS, as well as the related automation tools, a code can be automatically generated within seconds. Then, a real-time controller flashed within seconds, so that experimental activities can really be started early. This is the essence of rapid control prototyping!

- No programming skills needed

Graphical control design together with automated code generation is truly easy! Learning a programming language is entirely dispensable.

- Accurate simulations

The Simulink and PLECS blocksets contain simulation models that guarantee accurate simulation results.

- Facilitated code maintenance

The ability to conduct both the simulation and control generation tasks from the same files greatly simplifies code maintenance.

Related products

Want to know more?

For all questions related to our software, feel free to get in touch with our technical team. We're here to help! Online demos can also be organized upon request.

Alternatively, you can always download and install the software. As our licenses are hardware-related, our software is essentially unrestricted and all features can be tested free of charge.