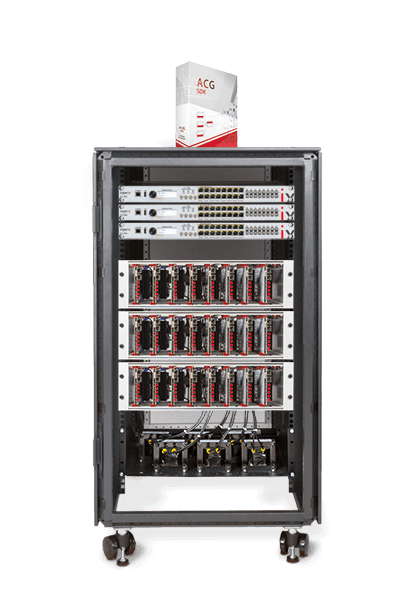

Bundle content

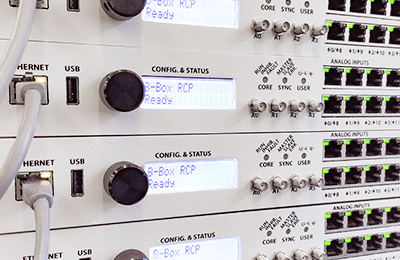

- 3x B-Box RCP

- 24x submodules

- 6x inductors

- 4x voltage sensors

- 6x current sensors

- 1x Grid-side panel

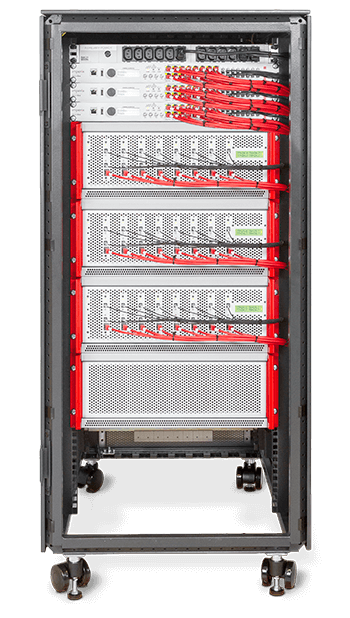

- 1x light 19” rack

- RJ45 and fiber cables

- Blockset for Simulink

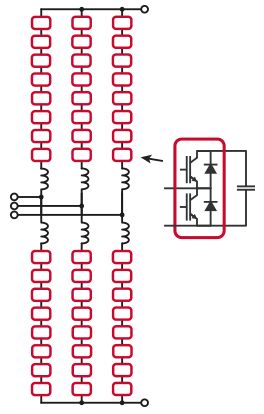

Modular Multilevel Converter

Ready-to-use test bench

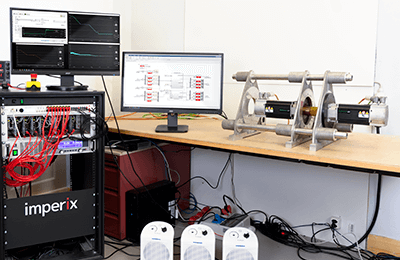

The Modular Multilevel Converter test bench is a ready-to-use prototype of an MMC.

The MMC test bench is proposed as a conventional DC/AC MMC inverter topology, but it can also be easily re-wired to support other types of multilevel and/or modular converters.

The system is aimed at supporting research related to the control of MMCs and its practical validation on a laboratory-scale power converter.

| your price |

More than a simple multilevel inverter

truly modular converters

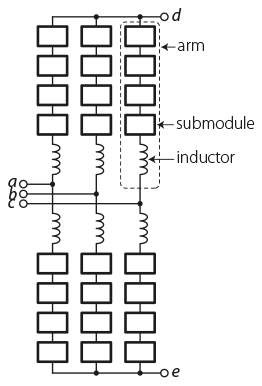

The Modular Multilevel Converter test bench is constructed in a modular fashion, the same way as larger power converters from this family.

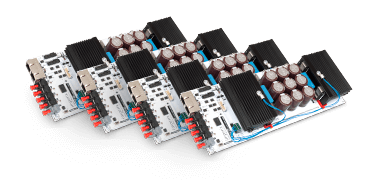

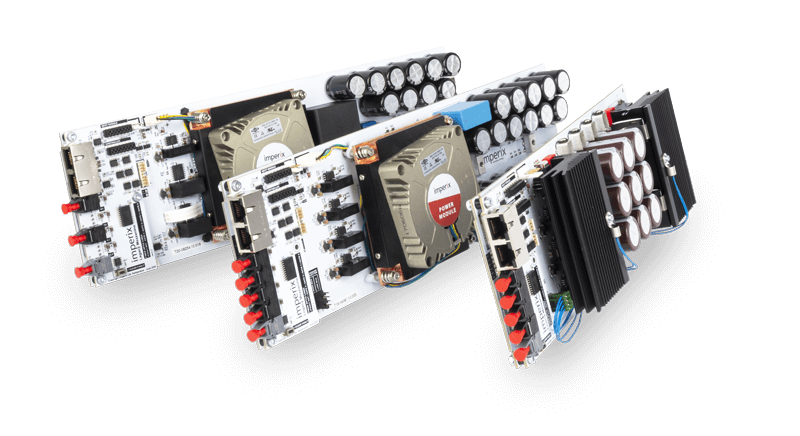

Both the power and the control stages are built using standardized identical elements. Notably, the Modular Multilevel Converter cells – or submodules – can be freely selected among the list of available imperix power modules.

Thanks to this high degree of modularity, various types of multilevel inverters can be easily built. Research engineers only need to rearrange the submodules and their wiring.

On the control side, the three units of the B-Box RCP prototyping controller offer various possible configurations, ranging from entirely centralized control to hierarchized and distributed control implementations.

Finally, when not used as part of a Modular Multilevel Converter mock-up, all products – control and power sides – can be also implemented to form more conventional power converter topologies.

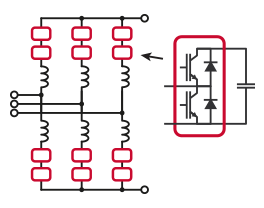

DEFAULT MMC CONFIGURATION

- 3x controller units

- 24x half-bridges submodules

A Modular Multilevel Converter at the laboratory size

Our ready-to-use Modular Multilevel Converter is designed for operation on the 230/400 VAC domestic grid voltage. This makes it an accessible downsized variant of the high-voltage industrial converters. Its structure and operation are identical to those dedicated to high-voltage DC transmission systems (HVDC), except the reduced power ratings.

MODULAR CONTROL HARDWARE

Imperix controllers can be very easily stacked, thanks to a Gigabit optical fiber connection. Up to 64 units can be directly interconnected.

MODULAR POWER HARDWARE

Different types of MMC submodules are available, including full-bridge, half-bridge and NPC-type configurations.

MODULAR CONSTRUCTION

The submodules can be mounted within 19” rack-mountable frames, so that their connections can be re-arranged when needed.

Modular multilevel converter family

A broad range of topologies and applications

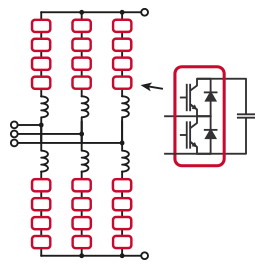

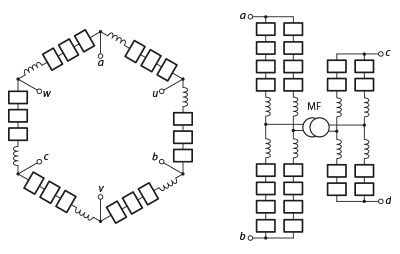

Unlike other ready-to-use laboratory test benches that implement a fixed topology (e.g. three-phase MMC inverter), this Modular Multilevel Converters test bench remains entirely independent from the studied topology. Other MMC topologies can be implemented with the exact same hardware.

Here are some examples – among many others – of multilevel power converters that can be implemented with the content of the standard test bench.

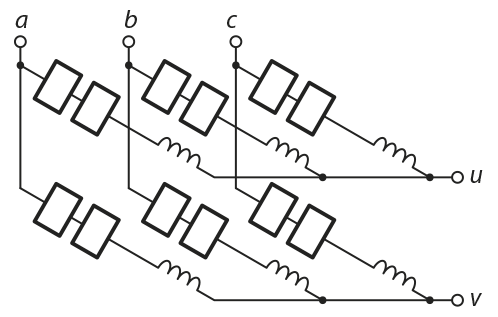

DIRECT AC/AC MMC

- 3x controller units

- 12x full-bridges submodules

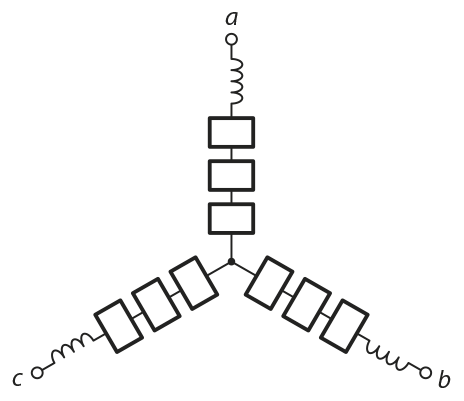

STAR-CONNECTED STATCOM

- 3x controller units

- 9x full-bridges submodules

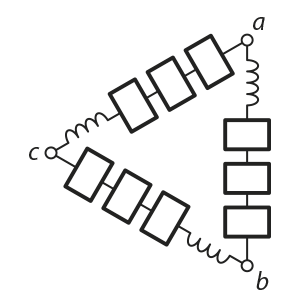

DELTA-CONNECTED STATCOM

- 3x controller units

- 9x full-bridges submodules

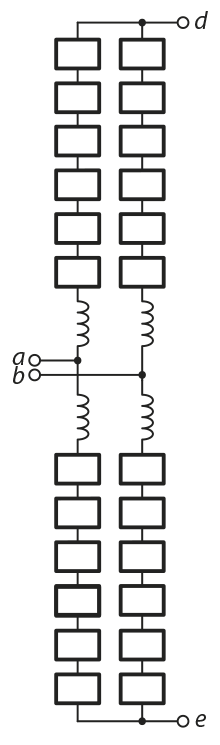

SINGLE-PHASE DC/AC MMC

- 3x controller units

- 24x half-bridges submodules

The Modular Multilevel Converter test bench isn’t limited to MMC. There are many more applications that can be addressed with the same hardware. Users should rather see it as a platform for research on this modern family of power converters.

N. Cherix, lead engineer at imperix

A system saving time and efforts

Key benefits for research

Implementing a Modular Multilevel Converter prototype can often be a time-consuming task, which may also drift control engineers away from their main focus.

In this sense, the MMC test bench is a solution that entirely bypasses this duty, offering an immediately usable support for most research activities.

Get instantly started with MMC

The Modular Multilevel Converter test bench is the perfect solution for catching up with recent research on this particular family of converters.

Publish results more quickly

With the constant pressure for innovative results, working with a reliable hardware prototype can bring significant leverage on the competition.

| Turnkey code examplesImperix provides several ready-to-use code examples for use with the Modular Multilevel Converter test bench. These can be downloaded directly from the website and implemented using Matlab Simulink. |

| Pre-implemented sort-&-select modulatorsThe well-known sort-and-select approach for balancing the submodule capacitor voltages is pre-implemented within a dedicated multilevel modulator. This guarantees successful operation for day one! |

| Pre-wired system upon requirementsRegardless of the studied topology, the Modular Multilevel Converter test bench can be delivered pre-wired with the desired configuration. This way, research engineers can immediately focus on the control. |

Configurable inter-modules connections

Thanks to the wired interconnections of the submodules, switching between full-bridge or half-bridge operation is a child’s play. Also, the overall converter topology can also be altered the same way.

Fully-open programmable controllers

Most research activities require complete access to all control layers. With B-Box RCP, both the DSP and the FPGA can be 100% freely edited, guaranteeing that any control strategy can for sure be implemented.

Re-usable equipment for the lab

Imperix controllers and power modules are not solely dedicated to research on Modular Multilevel Converters. The same products can be easily re-used for other projects and applications, for instance for teaching purposes.

Configurable number of MMC submodules

SCALABLE Modular Multilevel converters

Scalability is the essence of Modular Multilevel Converters. Therefore, the MMC test bench is scalable too!

The default configuration contains three control units and 24 submodules, however other variants are of course possible. The only constraints are that the number of PWM and analog I/O must match, plus that the maximum DC bus voltage remains below 1kV. From there, engineers can build up the system of their dreams.

Default Modular Multilevel Converter configuration

- Number of submodules per arm: N = 4

- Number of l-l voltage levels: max 17 levels

- Maximum DC voltage per submodule: Vsm = 200V

- Total DC bus voltage: VDC,max = 800V

A Modular Multilevel Converter “a la carte”

Hardware customization options

OTHER MMC SUBMODULE TYPES

All power modules from imperix can be used within Modular Multilevel Converter configurations. That said, the most convenient ones are certainly the PEH2015.

OTHER 19” ENCLOSURES

The submodules can be placed inside open frames or fully enclosed boxes. Each rack can accommodate up to eight submodules.

OTHER MMC TOPOLOGIES

Our technical staff can prepare a hardware configuration and wiring for most topologies. Simply contact us for more information.

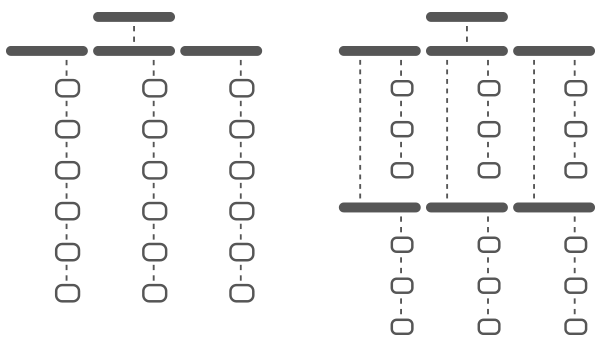

Control hierarchization for modular multilevel converters

Multi-controllers arrangements

Perfect synchronization

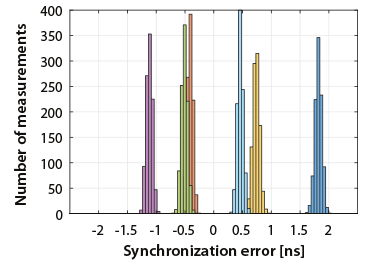

Imperix’s patent-pending RealSync technology offers unrivalled synchronization accuracy across multiple units, down to ± 2.0 ns! This enables multiple B-Box RCPs to operate as if they were one single unit!

High-speed communication

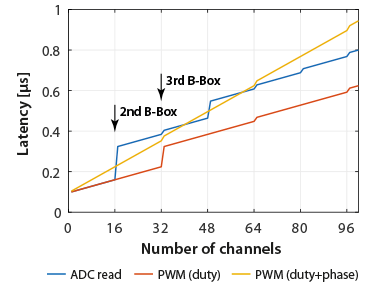

RealSync is meant to operate in a tree-shaped network topology, which guarantees lower latency over daisy-chain or ring topologies, with typically sub-μs data transfers in configurations with 8 controllers!

Distributed control is ideally suited for Modular Multilevel Converters as it enables various possibilities of control hierarchization, from purely centralized control to purely distributed control.

As soon as B-Box or B-Board controllers are connected, they are immediately synchronized, with ±2.0ns accuracy.

In distributed modulation applications, slave modulators can be updated with an extremely low latency.