Rack mounting solutions

Mechanical integration options for power modules

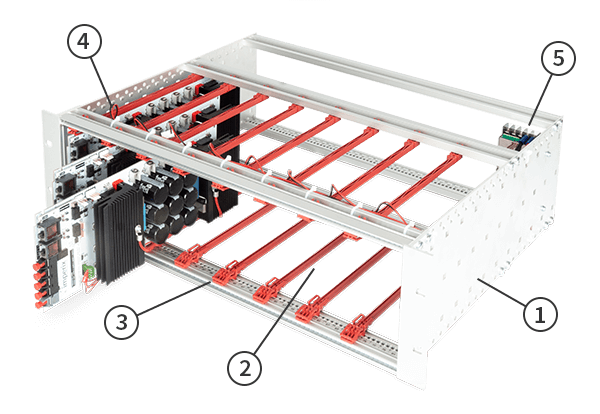

Imperix power modules are designed for easy rack mounting within 19” systems. This offers a simple way to build easily reconfigurable power converter systems.

Two approaches are available: open racks for handy and affordable integration, and closed racks for sleeker and safer configurations.

Rack mounting of power modules

Mechanical integration options

Imperix power modules can be assembled inside 19” rack-mountable structures. In essence, two different integration options are available, with differences in terms of:

- Ease of use when reconfiguring the converter topology

- Type of power connectivity.

- Type of air cooling.

- Mechanical protection level.

The following table shows the existing mechanical variants:

- Type A: Open rack for up to eight PEB or PEN modules.

- Type B: Open rack for up to eight PEH modules.

- Type C: Closed rack for up to six PEB modules.

- Type D: Closed rack for up to six PEN modules.

A modular approach of power electronics

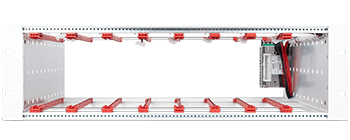

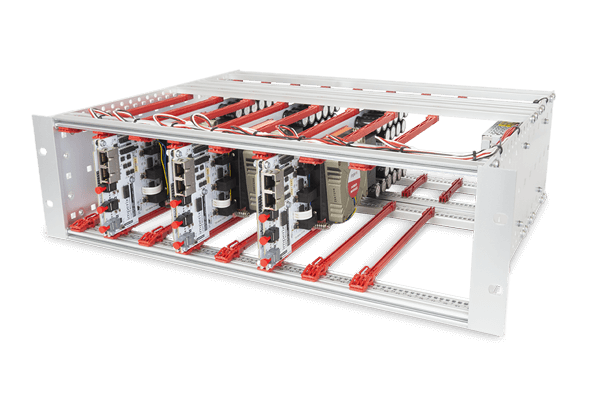

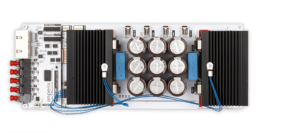

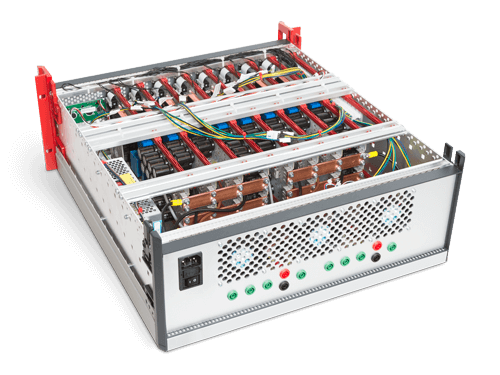

Rack-mountable chassis (3U)

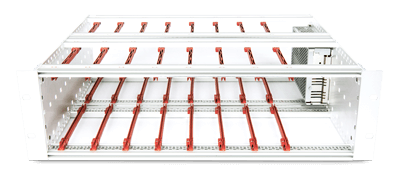

The use of open frames is certainly the easiest way to arrange imperix power modules on a table or within a cabinet. They offer an affordable, yet handy integration that can be easily adaptable and upgradable to meet the needs of your various projects.

Our 3U rack-mountable chassis includes a power supply and modules remain easily accessible, hence facilitating measurements and rewiring.

| FEATURE | TYPE A | TYPE B |

|---|---|---|

| Reinforced chassis (3U) | ||

| Sets of guiding rails (16x) | 160 mm | 220 mm |

| Module retainers | ||

| Power supply | 12V/5V | 5V |

| Internal wiring | ||

| Power connectors | rear | top |

- – 3U reinforced chassis

- – 8x slots for power modules

- – Module retainers

- – Internal wiring

- – Auxiliary power supply

| |

OPEN RACK – TYPE A |

| |

PEB8038 – 800V/38A |

| |

PEB8024 – 800V/24A |

| |

PEB4050 – 400V/50A |

| |

PEN8018 – 800V/18A |

| |

OPEN RACK – TYPE B |

| |

PEH2015 – 200V/15A |

| |

PEH4010 – 400V/10A |

Reconfigurable power converters

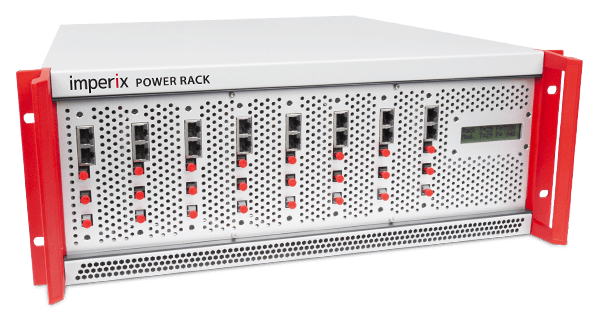

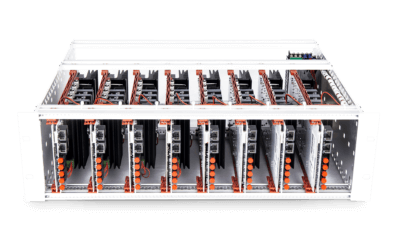

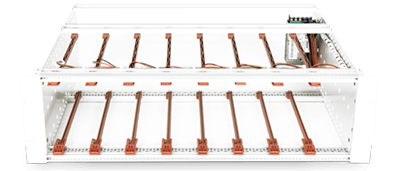

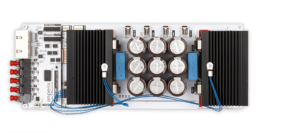

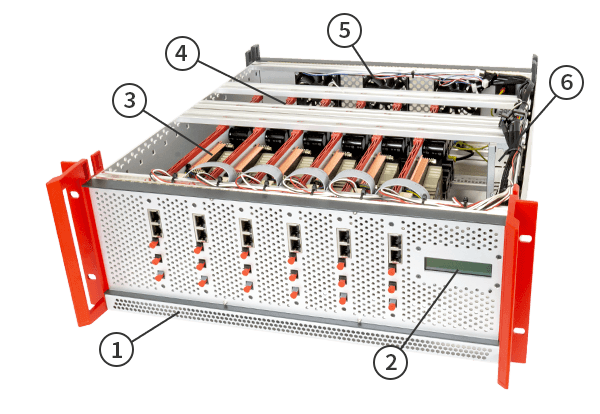

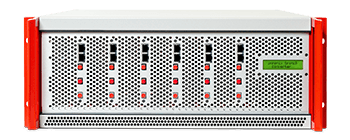

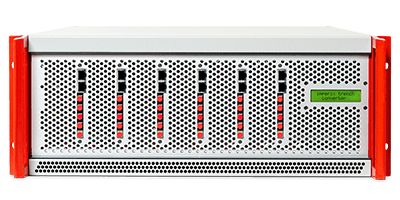

Power converter enclosures (4U)

Closed racks offer a sleeker and safer rack mounting of the power modules, where all hazardous voltages are out of reach. Nevertheless, they still give access to all signals and all power terminals for easy topology alteration. What’s more, an LCD screen displays useful information, such as module temperatures or fan speeds.

These enclosures are ideal for building fully-reconfigurable inverters, or any other power converter topology. Indeed, as all modules remain independent, 4U enclosures can be used to build up any structure, thanks to simple rewiring.

- Back-to-back power inverters / rectifiers

- Energy storage systems (chargers)

- Multilevel converters

- etc.

- – 4U reinforced chassis

- – LCD display

- – 6x power modules

- – Internal wiring for rear safety connectors

- – Cooling fans

- – Auxiliary power supply

Rear connectors – Type C

The rear panel gives access to all the power terminals: DC+, DC- and AC, with 4 mm safety connectors.

| |

CLOSED RACK – TYPE C | only available with power modules |

| |

6x PEB8038 – 800V/38A |

| |

6x PEB8024 – 800V/24A |

| |

6x PEB4050 – 400V/50A |

Rear connectors- Type D

The rear panel gives access to all the power terminals: DC+, DC-, AC and N, with 4 mm safety connectors.

| |

CLOSED RACK – TYPE D | only available with power modules |

| |

6x PEN8018 – 800V/18A |

Alternative rack mounting options

Customizable solutions

Ask us to customize your power converter according to your needs

Various alternative rack mounting solutions are possible, notably in order to facilitate the integration of imperix reconfigurable power converters into an existing research laboratory. A typical use case is to implement bus bars for two groups of modules instead of having entirely independent modules. This reduces parasitics and isn’t limiting the reconfigurability for most inverter configurations.

Please us the contact form to specify your needs and a development engineer will get back to you shortly. Customization can include, for instance:

- A different layout of the rear panel

- Other power connectors

- Embedded passive components

- Different enclosure