B-Box RCP

Rapid prototyping controller, research applications

B-Box Micro

Desktop controller, teaching applications

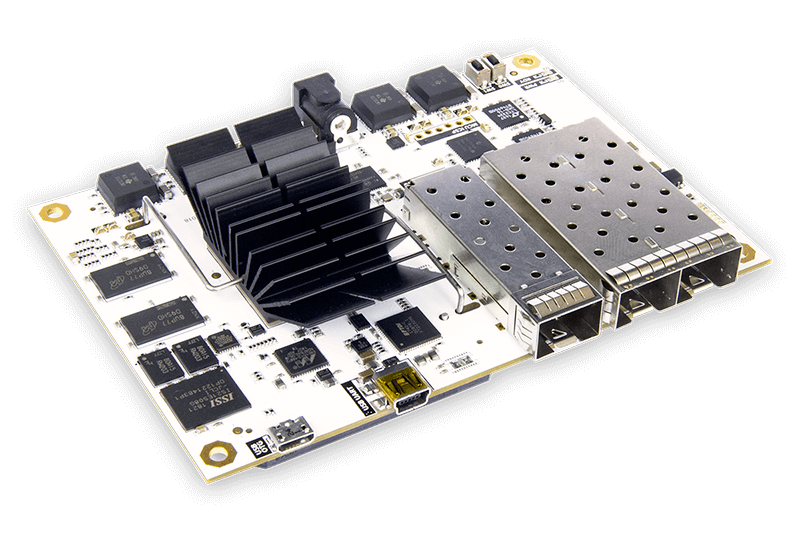

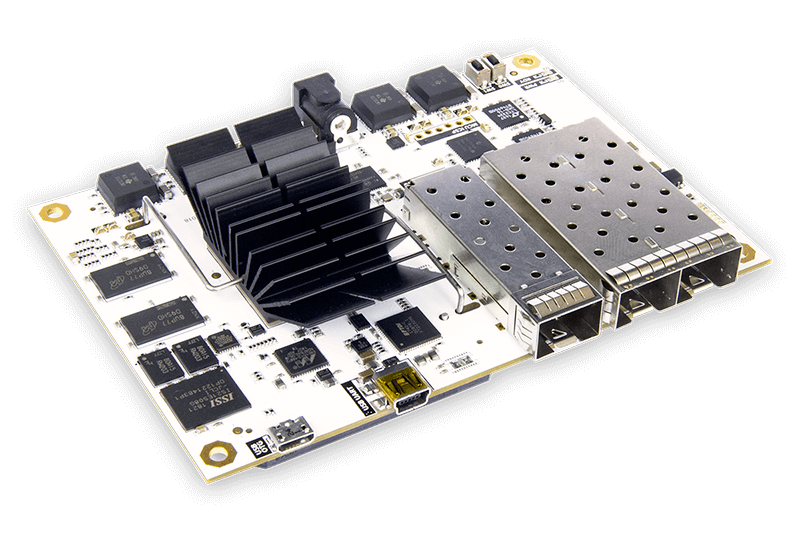

B-Board PRO

Embeddable controller, industrial applications

Power electronic controllers

Specialized control solutions

Fully-programmable DSP+FPGA digital controllers for power converters

Thanks to the high flexibility of their software and hardware, our power electronic controllers facilitate the prototyping and experimental validation of control techniques for all sorts of power converters.

Digital controllers for power electronics

A complete family of power electronic controllers

Our programmable controllers help engineers design, test, and validate digital control techniques for power converters. They enable them to save time during both development and product prototyping phases, thanks to their high level of specialization.

Typical applications include electric motor drives, grid-tied inverters (e.g. solar inverters), energy storage systems (e.g. batteries), or multilevel converters. Our control hardware includes two control systems for two distinct use cases:

- B-Box RCP is a rapid control prototyping system, dedicated to laboratory applications.

- B-Box Micro is a table-top controller, dedicated to teaching applications.

- B-Board PRO is a fully programmable controller that can be directly embedded inside power converters

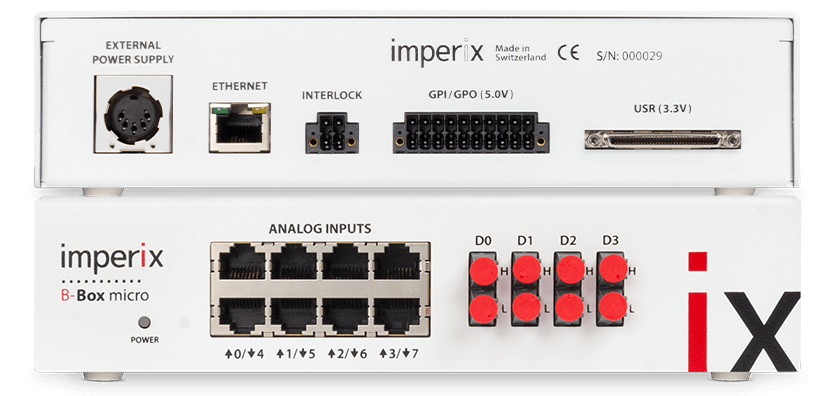

B-Box Micro

Cost-effective controller

- Limited I/Os

- Directly plug-&-play with imperix

power modules - User-programmable FPGA

- Firmware-level protections

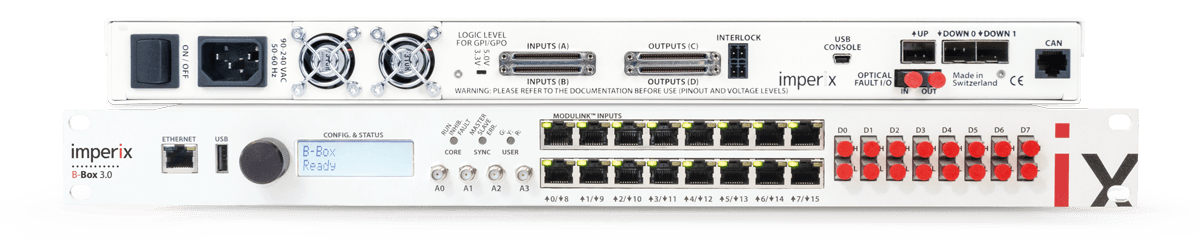

B-Box RCP

Flagship controller

- Numerous I/Os

- Suitable for distributed control

- Configurable analog front-end

- Directly plug-&-play with imperix

power modules - User-programmable FPGA

- Hardware-level protections

B-Board PRO

Embeddable controller

- Numerous, board-level I/Os

- Suitable for distributed control

- Small form factor

- User-programmable FPGA

- Software-level protections

B-Box RCP

Flagship controller

- Numerous I/Os

- Suitable for distributed control

- Configurable analog front-end

- Directly plug-&-play with imperix

power modules - User-programmable FPGA

- Hardware-level protections

B-Box Micro

Cost-effective controller

- Limited I/Os.

- Directly plug-&-play with imperix

power modules - User-programmable FPGA

- Firmware-level protections

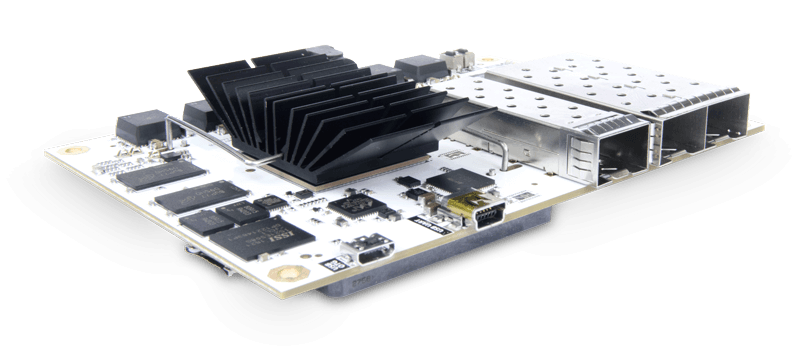

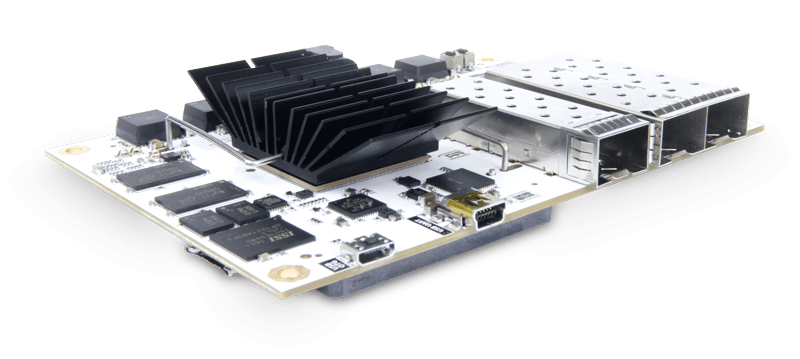

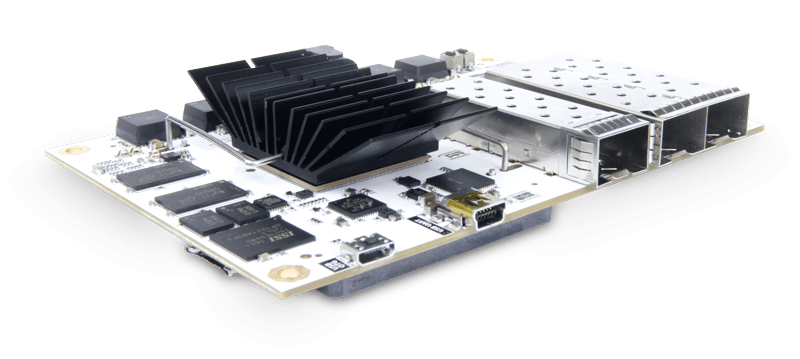

B-Board PRO

Embeddable controller

- Numerous, board-level I/Os

- Suitable for distributed control

- Small form factor

- User-programmable FPGA

- Software-level protections

| B-Box Micro | B-Box RCP | B-Board PRO | |

| System on Chip | Zynq SoC (2x 1GHz + Kintex 7 125K) | ||

| Number of ADC-channels | 8x | 16x | 8x |

| Number of PWM-signals | 8x optical | 16x optical 32x electrical | 32x electrical |

| Number of USR I/O | 36x | 36x | 36x |

| Number of GPI/GPO | 16x / 8x | 16x / 16x | 16x / 16x |

| Distributed control (SFP) | |||

| Plug-&-Play compatibility | |||

| Programmable analog frontend (impedance, gain, filter) | |||

| Protections | at firmware-level | at hardware-level | user software only |

A common workflow with unified software

All imperix controllers can be used similarly and programmed using the same blockset or C/C++ functions. During testing, or when simply monitoring the system during operation, the same experience is also offered within imperix Cockpit.

1 – System programming

The digital controllers can be easily programmed using C/C++ code or using our automated code generation toolboxes for Simulink and PLECS.

All it takes to flash a user code on a target hardware is only one click. Code generation, compilation, and upload are fully automated. Besides, no particular skills are needed.

2 – Run-time execution

The controllers can be used alongside a computer or as standalone devices. In both cases, direct access to the code execution is guaranteed by the Cockpit software.

All control targets can be used to build fully-programmable power converters. Both the DSP and FPGA can be edited and have their parameters tuned during run-time.

3 – Live monitoring

The programmable controllers support real-time access so that engineers can monitor and tune any variable, facilitating the debugging and/or maintenance of the control software.

The monitoring utility also provides datalogging capabilities similar to an oscilloscope. This allows logging every data point or observing control variable over longer time intervals.

B-Box RCP

DSP+FPGA controller for rapid control prototyping applications

The B-Box RCP is a highly flexible power converter control system, tailored for rapid control prototyping applications in power electronics. Thanks to its high performance and flexibility, it facilitates the experimental validation of power converters control techniques in laboratory environments.

Keywords:

- Rapid prototyping controller

- Inverter control hardware

- Electric motor drive controller

- Power converter controller

- Programmable inverter controller

- DSP+FPGA control system

TAILORED DESIGN

Also, the controller has been designed to guarantee a very strict management of timings, from analog inputs to PWM outputs, including in stacked configurations.

HIGH-END DESIGN

Together with an ultra-light and specialized operating system, this guarantees state-of-the-art performance for all closed-loop control applications. Running a converter control algorithm in the hundreds of kHz range becomes no longer a challenge!

SCALABLE DESIGN

Multiple converter control units can be stacked together to build up larger controllers. Up to 64 boxes can be combined, extending up to thousands of I/Os!

This brings high flexibility in time and across multiple projects. It is always possible to combine (or separate) units depending on the varying needs of their applications.

FUTURE-PROOF DESIGN

This way, it is guaranteed that a code that works today will still work in the future, even though the hardware will most certainly change in-between.

B-Box MICRO

TABLE-TOP CONVERTER CONTROLLER FOR TEACHING APPLICATIONS

The B-Box Micro is a small but mighty power inverter controller ideally suited for teaching applications. Its easy-to-use software environment makes it possible to switch faster from simulation to experimentation without taking any safety risks even for inexperienced users.

Keywords:

- Programmable inverter controller

- Table-top inverter controller

- Power converter controller

- DSP+FPGA control system

- Teaching power electronics

- Power laboratory equipment

COST-EFFECTIVE

The B-Box Micro is a cost-effective controller that enables the realization of plenty of different power electronic applications and inverter topologies at an attractive price.

PLUG-&-PLAY

This controller provides all the necessary I/O connectivities to use it together with imperix power modules, voltage, and current sensors. Many diverse application examples are available on the imperix knowledge base.

Hence within a very short time, a basic power inverter can be cabled, programmed, and put into operation.

GRAPHICAL PROGRAMMING

The B-Box Micro can be programmed in C/C++ or directly from simulation software, such as Simulink or PLECS. Thanks to a fully automated code generation toolchain, just one single click is all it needs to fully program the device!

The provided blocksets embed simulation models so that the system behavior can be accurately simulated and tuned before run-time.

SUITED FOR TEACHING

The configurable safety limits on the B-Box Micro can protect power semiconductors so there is no need to worry about handling the device to students, once they are correctly configured. Additionally, the small form-factor solution saves space on laboratory stations.

Furthermore, the controller is versatilely applicable, so it can also be used for research purposes or student projects.

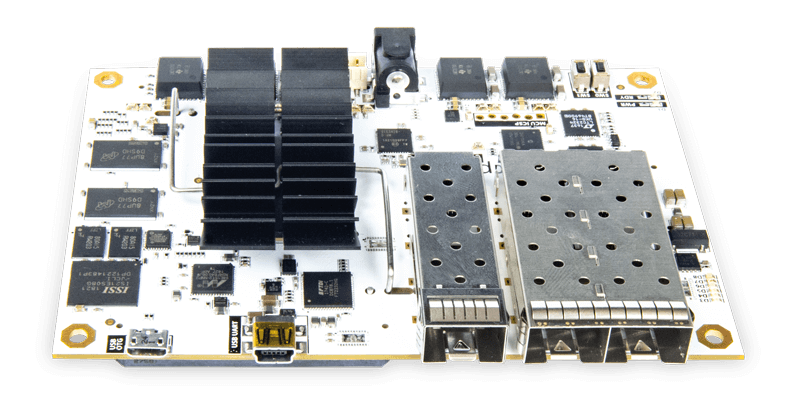

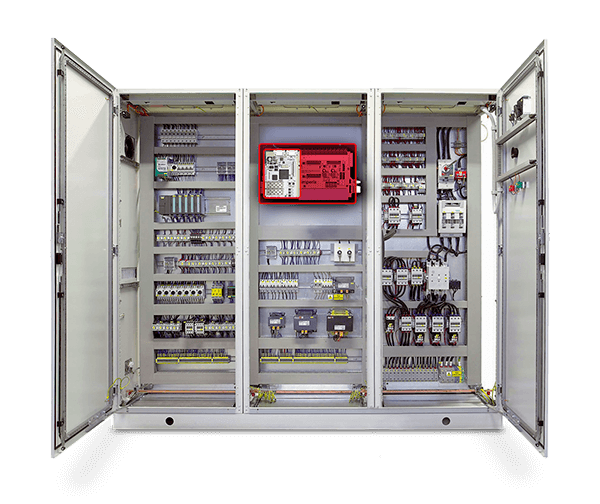

B-Board PRO

Converter controller module for product-embedded applications

The B-Board PRO is the heart of the B-Box RCP controller but it is also available as a standalone controller for embedded applications. The board feature a ZynQ-based dual-core ARM processor and a Kintex-grade FPGA (Xilinx Zynq), plus advanced communication capabilities and extensive I/Os.

Keywords:

- Embedded control board

- Programmable digital controller

- Converter control hardware

- DSP+FPGA control module

- Power inverter control module

INTEGRATED WITH SIMULINK AND PLECS

The digital control module can be programmed using either C/C++ or directly from simulation software, such as Simulink or PLECS. Thanks to a fully automated code generation toolchain, just one single click is all it needs to fully program the device!

The provided blocksets in Simulink and PLECS also embed simulation models so that the system behavior can be accurately simulated and tuned before run-time. Then, everything truly works from the first test!

USER-PROGRAMMABLE FPGA

Absolutely no expertise in FPGA-based development is needed to work with our embeddable controller, as it operates readily with a highly flexible and highly configurable FPGA firmware.

Nevertheless, for the most advanced users who require to alter the FPGA code, the module allows doing so. In this case, dedicated areas are provided, with straightforward integration within the existing DSP software.

HIGH PROCESSING POWER

This results in the full dedication of a fast floating-point processor core to real-time control tasks, with best-in-class performance, ranging up to 200kHz control frequencies in closed-loop operation.

QUICK INTEGRATION

Overall, most of the specific integration efforts are only those related to the mechanical aspects as well as the signal conditioning and protection, which are often tailored to the application anyway.

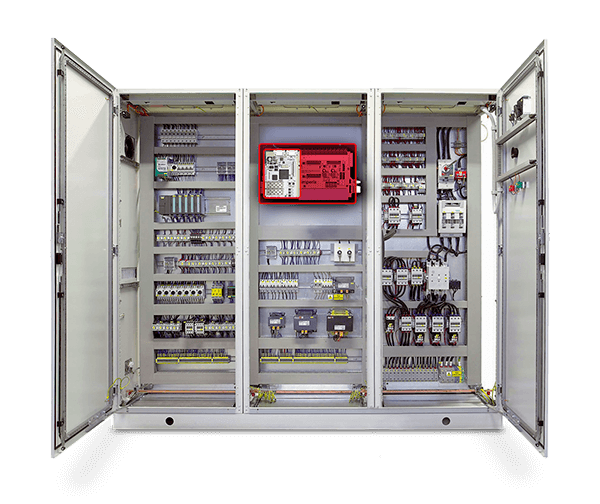

Complementary power electronic controllers

FROM THE LAB TO THE FIELD!

What if you could simply take the result of your research and put it into an affordable controller, directly embedded inside your own power electronic systems?

Development phase

- Flexible control hardware

- Rapid prototyping

Production phase

- Cost-optimized hardware

- Product integration

Embeddable controller

Prototyping controller

Development phase

- Flexible control hardware

- Rapid prototyping

Production phase

- Cost-optimized hardware

- Product integration

to go further

Software solutions

The Automated Code Generation (ACG) SDK enables engineers to program the power electronic controllers directly from Simulink or PLECS. The provided toolchain handles fully automated code generation, compilation, and upload in just one click.

In addition, the SDK contains simulation models of each controller peripheral, so that the exact behavior of the control system can be simulated – and hence easily anticipated – before code is generated.

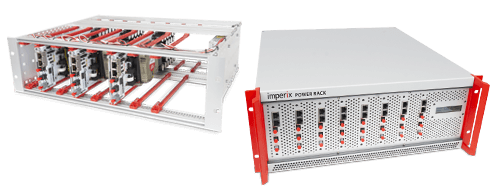

Power equipment

Imperix power modules are ready-to-use building blocks allowing to build up almost any converter topology. They exist in various power ratings and internal structures. Each module features:

- Power semiconductors

- Gate drivers

- Voltage and current sensors (with local protection)