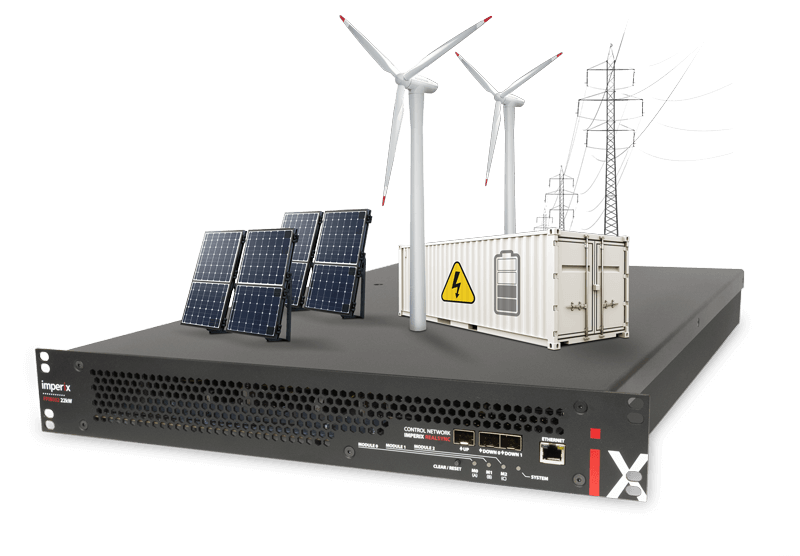

THE ALL-IN-ONE SOLUTION FOR MICROGRID APPLICATIONS

The programmable inverter is particularly suited for AC microgrid applications. It includes an LC filter and a comprehensive EMC filtering solution that strongly reduces the harmonic content of the voltages and currents. Furthermore, an automated precharge circuit simplifies the grid connection procedure. Finally, the embedded controller can be reprogrammed to fit any purpose: grid-forming, grid-following, regenerative grid emulator, electronic load, power amplifier, etc.

PROGRAMMABLE INVERTER

TPI8032 22KW

The TPI8032 is an all-in-one programmable inverter for 230/400 VAC three-phase applications. With its 22 kW power rating packed into a 1.5U 19″ rack form factor, the programmable inverter offers a high power density in a slim and compact chassis.

Unlike off-the-shelf industrial inverters, the TPI is fully programmable and allows the implementation of the most advanced control techniques on both its DSP and FPGA.

Thanks to its ultra-fast switching Silicon Carbide MOSFETs and its high-performance controller, the programmable inverter can notably be used for medium-frequency, hard-switched applications up to 150 kHz.

WHAT IS INCLUDED IN THE PROGRAMMABLE INVERTER?

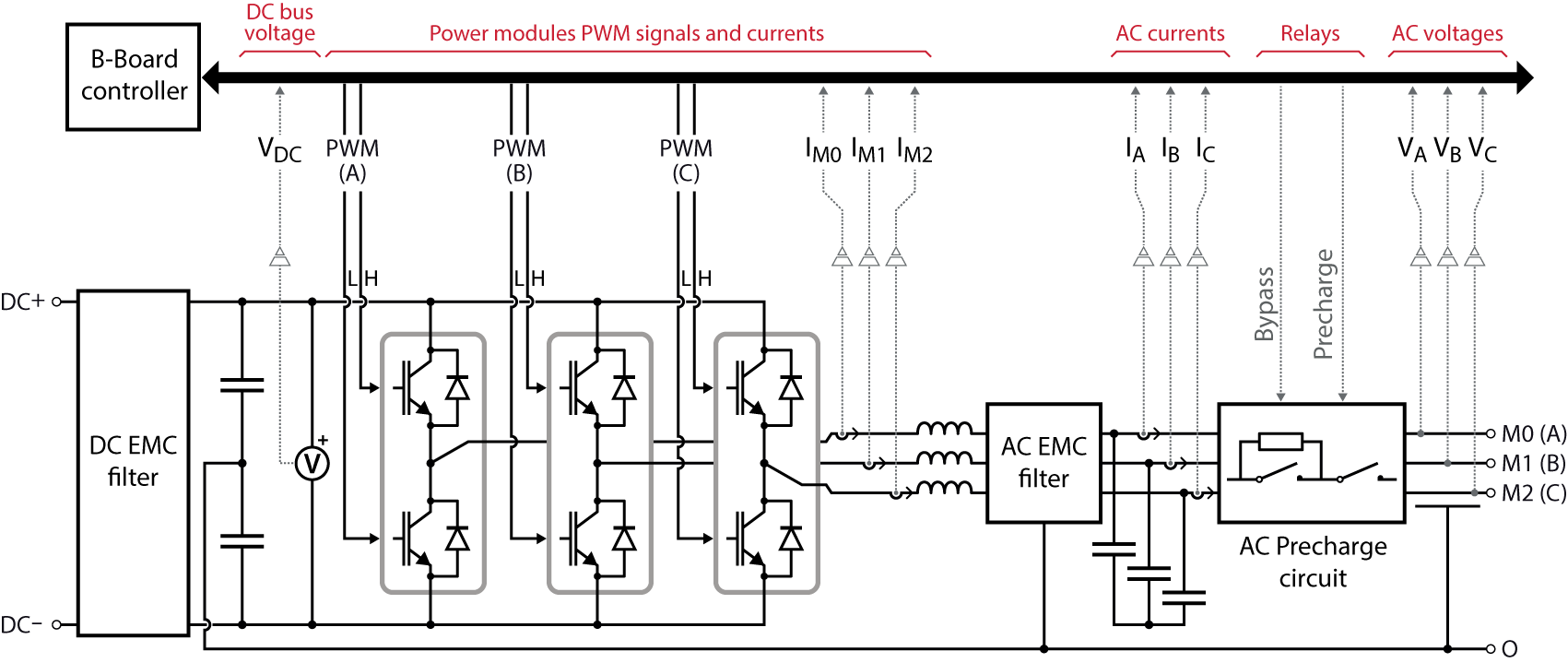

CONTROL AND POWER COMBINED INTO A COMPACT SYSTEM

As an all-in-one solution, the programmable inverter includes all the necessary equipment to implement and test the closed-loop control of a grid-tied inverter. It ranges from the power stage to the embedded controller, including a wide set of voltage and current sensors for feedback.

LC and EMC filters

A comprehensive filtering solution ensures excellent power quality, with quasi-sinusoidal output voltages and currents. As a result, the programmable inverter complies with the CISPR11 EMC standard.

Automated AC precharge circuit

The precharge procedure of the DC bus is fully automated and prevents the uncontrollable flow of currents through the anti-parallel body diodes of the MOSFETs. It enables safe and seamless connection to the grid.

Safe Operating Area (SOA) protections

SOA protections safely deactivate the power stage in case of hazardous behavior. They prevent the system from exceeding its rating during normal conditions and protect it against fast transient phenomenons (e.g. over-current/voltage).

TYPICAL APPLICATIONS OF THE PROGRAMMABLE INVERTER

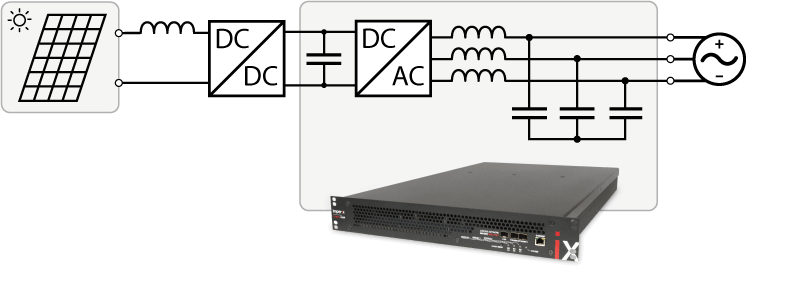

Grid Following Solar Inverter

A typical use-case scenario of the programmable inverter is to interface photovoltaic panels with the AC grid. In this application, the DC bus is precharged from the AC side, taking advantage of the automated precharge circuit.

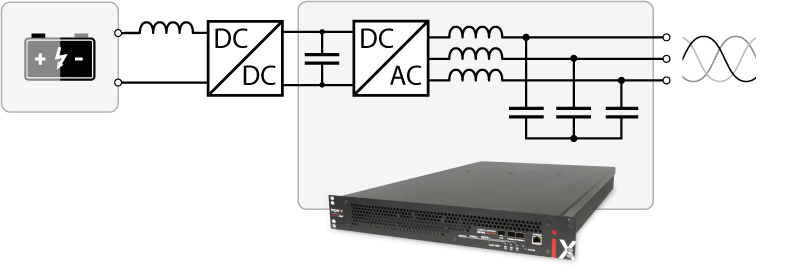

Grid Forming Inverter with battery storage

Another use case is a grid-forming inverter based on a battery energy storage system. Voltage and current sensors are strategically placed to facilitate the implementation of a cascaded voltage control, typically used as the inner loop of a droop control algorithm.

INTUITIVE PROGRAMMING WITH AUTOMATED CODE GENERATION

A FULLY PROGRAMMABLE INVERTER

High-performance embedded controller

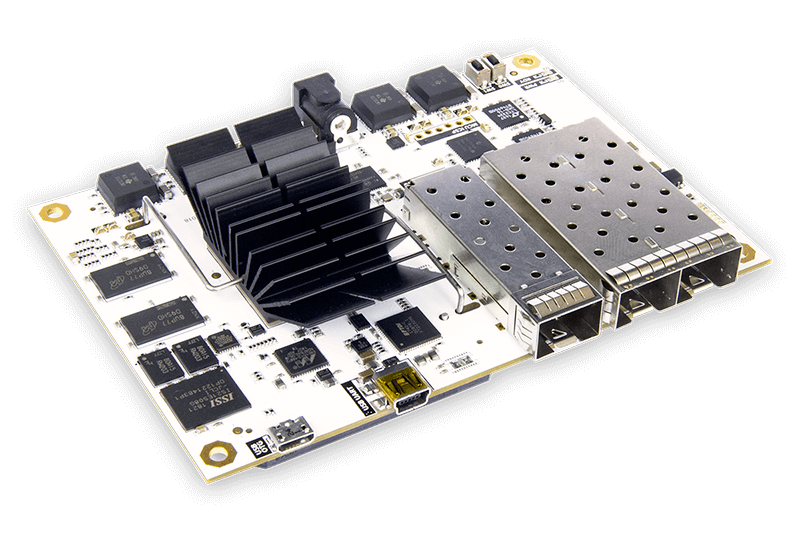

The embedded B-Board PRO controller uses a dual-core processor (Xilinx Zynq). One DSP core is dedicated to the real-time control tasks (bare metal, dedicated kernel), the other one to the system supervision and monitoring (Linux). Most low-level tasks are also shifted in FPGA.

This results in the full dedication of a fast floating-point processor (DSP) to power converter control purposes, with tremendous performance, ranging up to 400 kHz control frequencies in closed-loop operation.

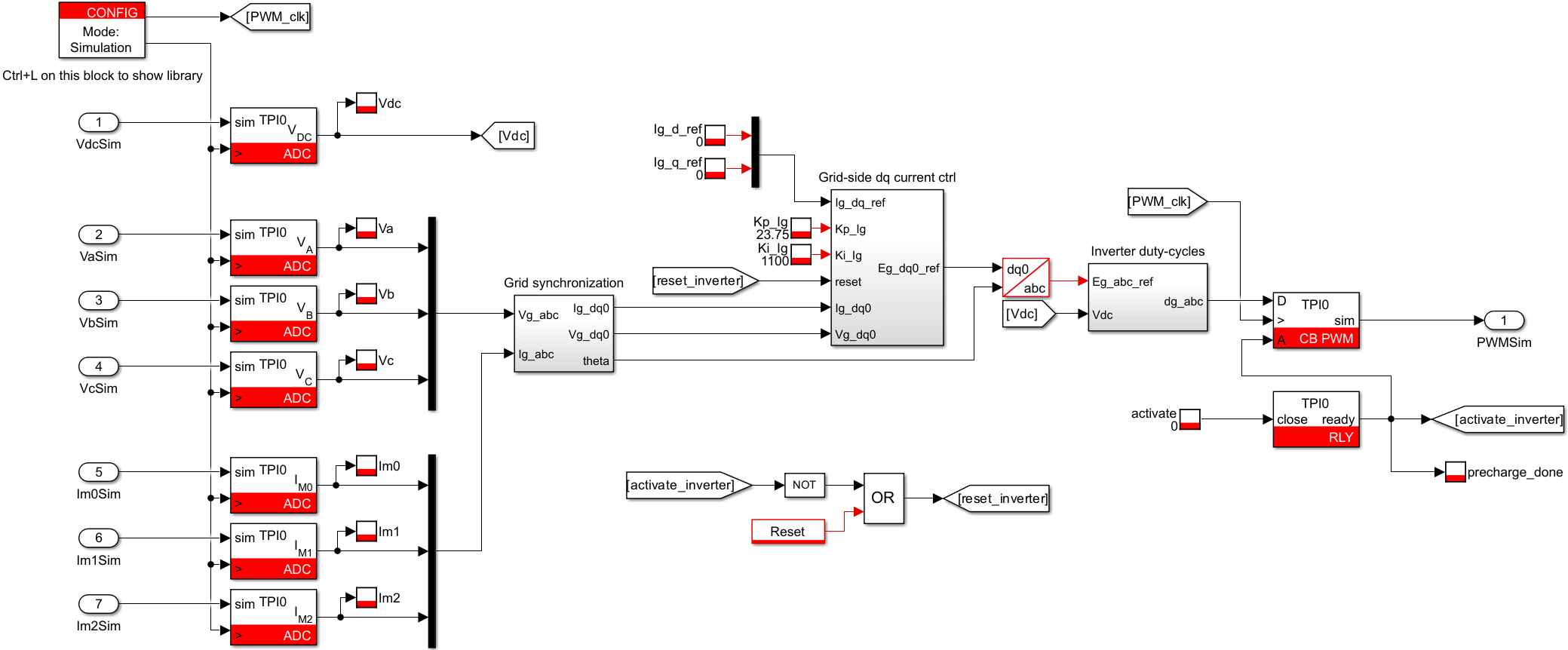

Graphical programming with Simulink or PLECS

The programmable inverter can be programmed using simulation softwares such as Simulink or PLECS. Thanks to our fully-automated code generation toolchain, just one single click is needed to fully program the device!

The blocksets also embed simulation models so that the system can be accurately simulated and tuned before code is generated.

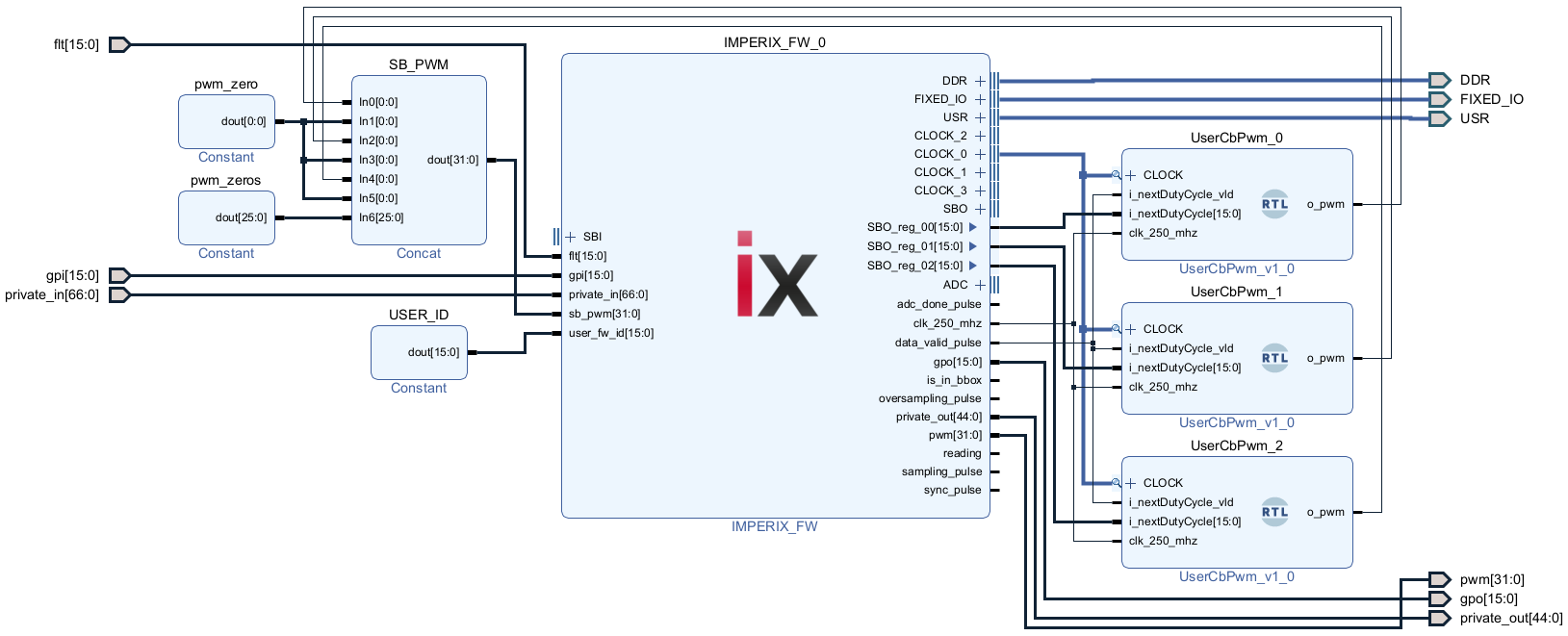

User-programmable FPGA

Absolutely no expertise in FPGA-based development is needed to work with the programmable inverter. It operates readily with a very flexible and entirely configurable FPGA firmware.

Nevertheless, for advanced users who require custom FPGA code, the embedded controller allows doing so. Dedicated FPGA areas are provided, with straightforward integration with DSP software.

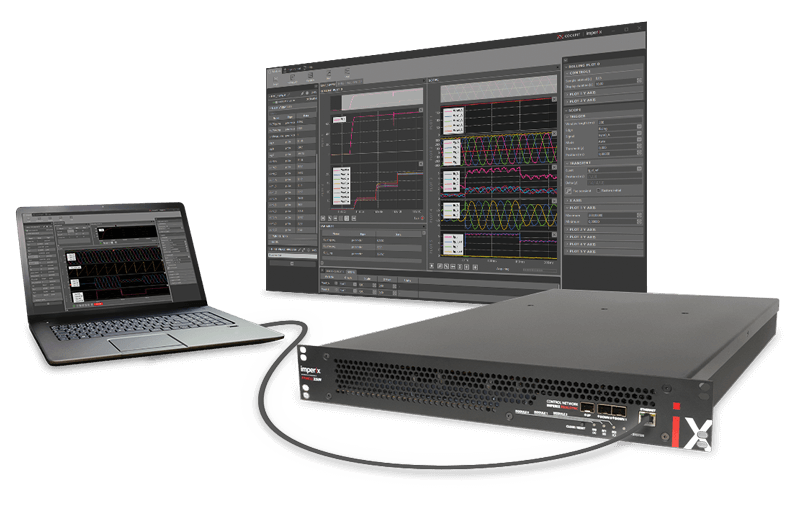

Real-time monitoring software

During operation, Imperix Cockpit allows observing, editing, and logging any variable present in memory. This facilitates the rapid debugging and tuning of any converter control code.

- Real-time tuning of all variables

- 2 million points datalogging

- Free maintenance

CONNECTIVITY AND INTERNAL LAYOUT

The programmable inverter is designed to be integrated into a 19″ rack cabinet. With its slim and compact enclosure, the inverter optimizes the use of space by favoring depth rather than height. Furthermore, the analog and digital connectivity provided at the rear of the rack makes it simple to add external sensors, relays, etc. Finally, the programmable inverter can communicate with other devices over SFP, ethernet, or CAN.

![]() Hover to find out more.

Hover to find out more.

FRONT VIEW

REAR VIEW

INTERNAL LAYOUT

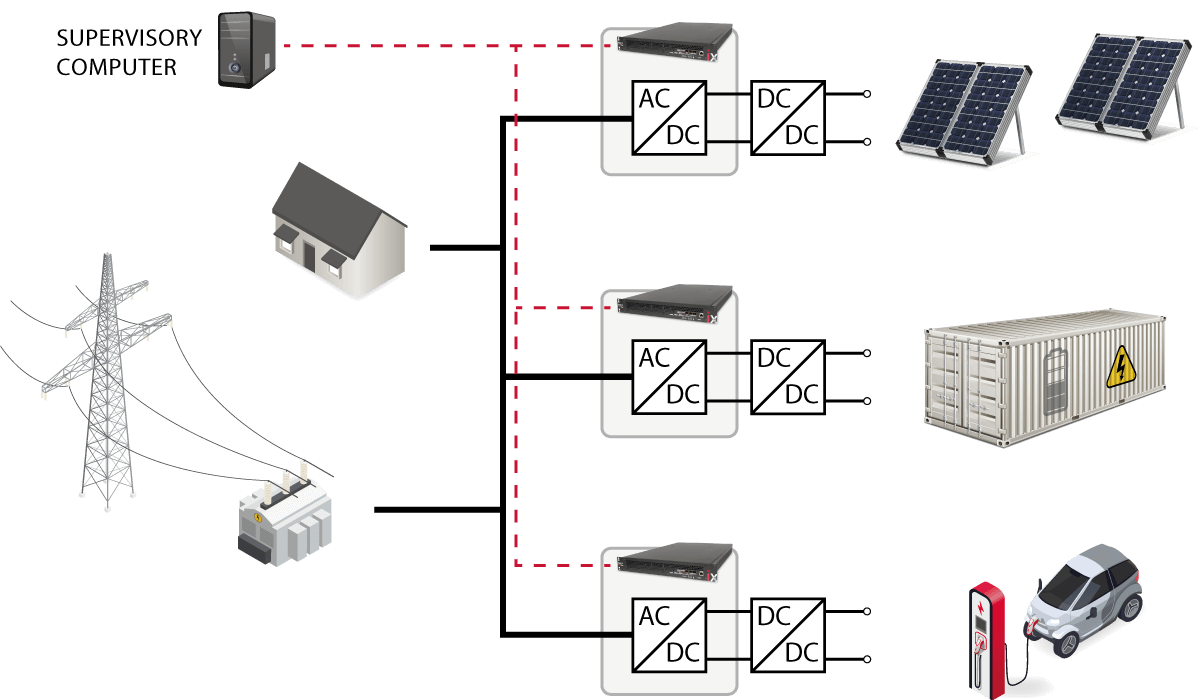

INTEGRATING DISTRIBUTED ENERGY RESOURCES INTO A SMART GRID

RESEARCH TOPIC EXAMPLES

One key research area related to grid-tied inverters is the integration of Distributed Energy Resources (DER) into electric power systems (EPS). In this context, the programmable inverter is a powerful development platform as it can be fully reprogrammed to implement any function related to interconnection, grid services, interoperability, energy management, etc.

- Droop control

- Virtual inertia

- Low voltage ride-through

- Anti-islanding

- Frequency-watt control

- Volt/VAR curves

- Synchrophasor estimation

- Virtual power plant

- Decentralized control

- Load shifting

- Model Predictive Control for battery storage

Grid support capabilities

State-of-the-art DERs are able to support the grid using various software-based techniques, which can be quickly implemented on the programmable inverter. It includes, for example, reactive power regulation using Volt/VAR curves or active ride-through strategies to withstand voltage and frequency disturbances.

Optimal energy management

The embedded B-Board controller offers plenty of processing power to tackle optimization problems. One such example is the energy management of a battery storage system based on Model Predictive Control (MPC). In fact low-level tasks (e.g. voltage/current control) can be implemented in FPGA to free up CPU time.

Distributed microgrid control

Multiple programmable inverters can operate as part of a control network using the imperix RealSync protocol for ultra-fast data exchanges. Alternatively, communication over ethernet is possible with third-party controllers, such as a Supervisory Control and Data Acquisition system (SCADA) master unit.

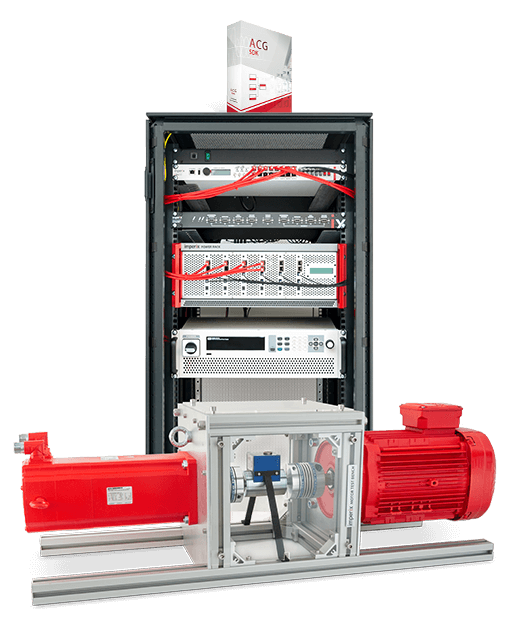

MODULAR ALTERNATIVES TO THE PROGRAMMABLE INVERTER

KITS AND BUNDLES

Imperix offers alternatives to the programmable inverter when modularity is more valuable than a compact all-in-one system.

HARDWARE + SOFTWARE

HARDWARE + SOFTWARE

HARDWARE + SOFTWARE