POWER INVERTER MODULES

BUILDING BLOCKS FOR MODULAR POWER CONVERTERS

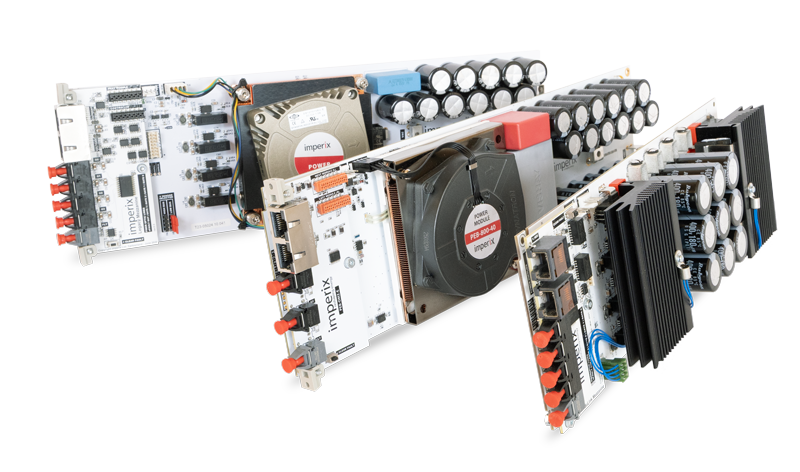

Imperix power modules are building blocks for the rapid implementation of power inverter prototypes, as well as all sorts of power converters. They are notably ideally suited for modular power converter topologies.

The power inverter modules are designed for use inside research laboratories, in order to facilitate the rapid prototyping and validation of various converter control techniques.

ACCELERATE CONTROL TESTING WITH POWER MODULES

BUILDING POWER CONVERTERS IN A FEW HOURS

Focus on the control rather than the hardware

While offline and online simulations provide meaningful insights for control algorithms, experimental validation is often required to prove their effectiveness and proper operation in the real world.

To this end, imperix power inverter modules can be a great help. Being ready-to-use modules, they can be quickly assembled to form all types of power converters. Besides, they offer plug-&-play compatibility with our rapid control prototyping system.

For these reasons, setting up a converter prototype requires no PCB development and is a matter of hours rather than months.

Standard solutions for specific needs

Our power modules are designed for both teaching and research applications within power electronics laboratories. They can ideally support control software testing for industrial power inverters, or simply illustrate basic converter control techniques within an educational context.

In all cases, thanks to their various internal structures, imperix standard modules can cover the vast majority of applications. This avoids the need for costly and time-consuming custom development. Inverter modules are available using either IGBT or MOSFET semiconductors.

PART OF A COMPREHENSIVE ECOSYSTEM

One of our power inverter modules’ greatest strengths is its integration into imperix ecosystem. Not only can end-users build converters in a few hours, but developing and testing algorithms is also a breeze thanks to our control solutions.

Monitoring software

Imperix Cockpit allows tuning variables online while providing a convenient oscilloscope-like interface for monitoring.

Power accessories

Common elements (passive filters, switchgear, additional sensors, etc) are also readily available as plug-&-play products.

TURNKEY BUILDING BLOCKS

POWER INVERTER MODULES FOR LABORATORY USE

NO HARDWARE DEVELOPMENT NEEDED

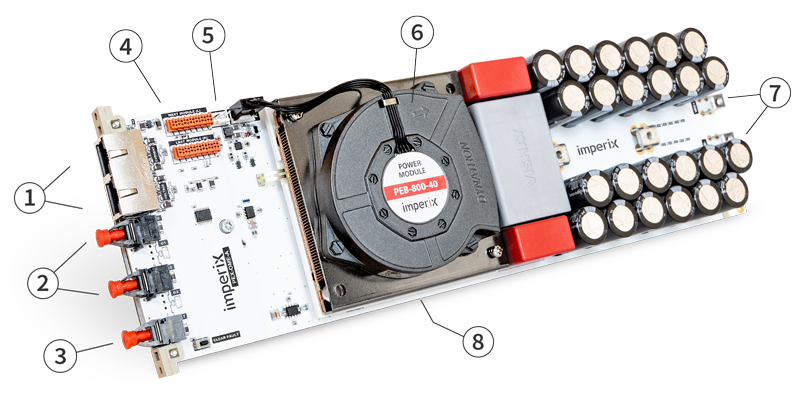

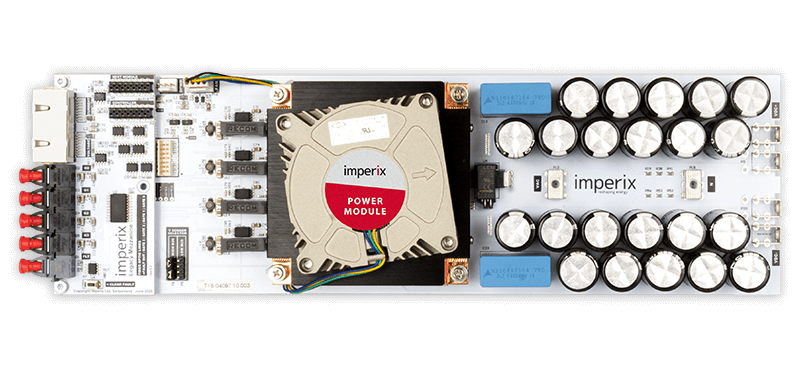

Imperix power inverter modules contain not only power semiconductors but also all necessary auxiliary circuits to ensure safe and proper operation.

As such, assembling converters only requires some wiring, with easily-accessible terminals for the DC bus and switching nodes.

FOR USE WITH A SEPARATE CONTROLLER

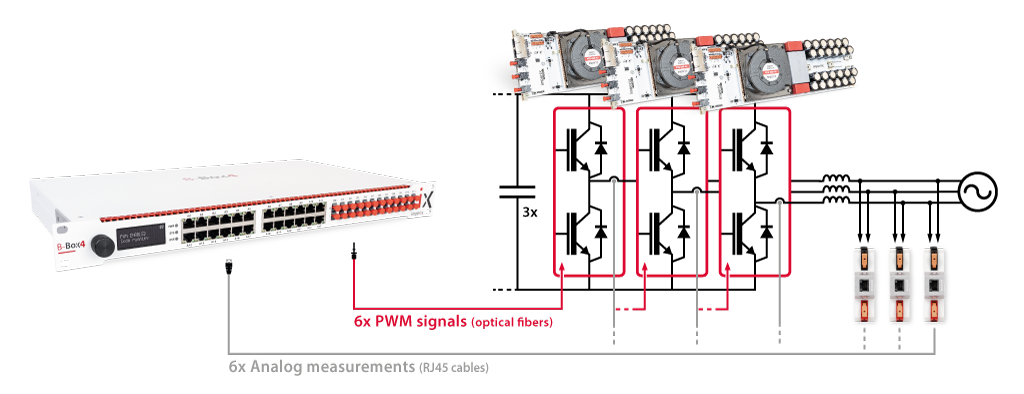

A separate controller executes the control algorithm and generates PWM gating signals. They are sent to the gate drivers through optical fiber inputs. Furthermore, on-board voltage and current sensors provide convenient access to measurements typically used in closed-loop control.

Imperix controllers are an ideal choice due to their ease-of-use and plug-&-play compatibility. However, using third-party controllers is also possible.

- – V/I Sensors outputs (analog)

- – Gate drivers inputs (optical)

- – Fault output

- – Board-to-board link

- – Power supply (5/12 V)

- – Cooling fan

- – DC link terminals

- – Power switches

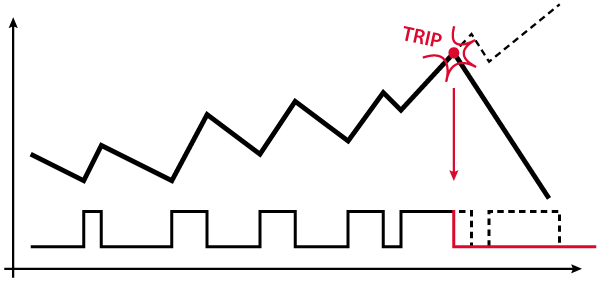

ROBUST AND SELF-SUFFICIENT SAFETIES

Power inverter modules can be safely put in the hands of inexperienced engineers thanks to their embedded safety mechanisms. This also ensures safe operation of the converter independently from the main controller and the control algorithm.

POWER INVERTER MODULES AND ALTERNATE TOPOLOGIES

A MODULE FOR EVERY NEED

Half-bridge module

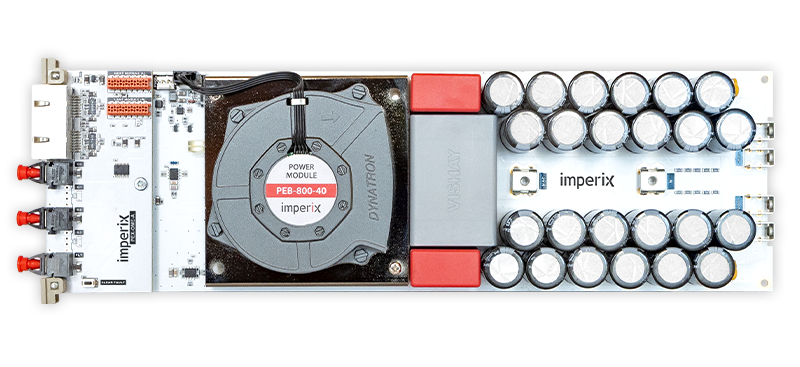

PEB-800-40 – 800V/40A

Grid-connected inverters and motor drive applications, up to 9kVA per module.

Half-bridge module

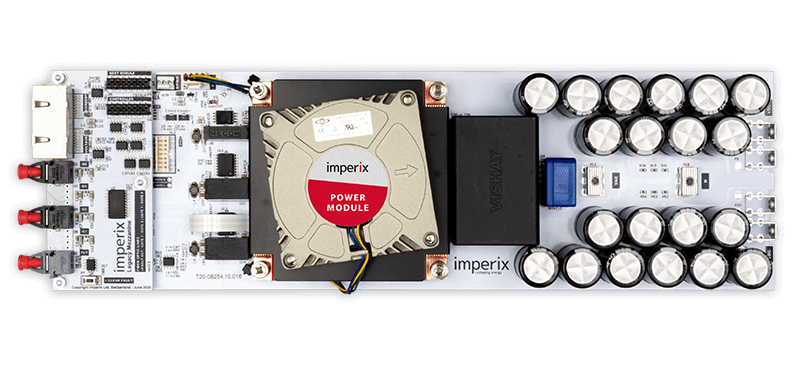

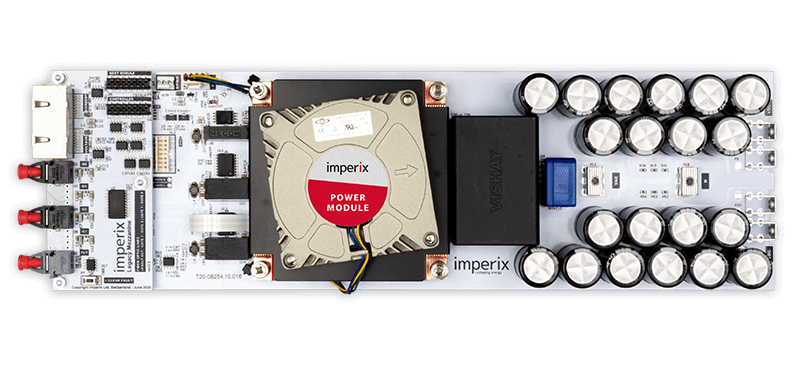

PEB4050 – 400V/50A

120VAC, teaching and general-purpose applications, up to 6kW per module.

Half-bridge module

PEB8038 / PEB8024

Legacy products superseeded by the PEB-800-40.

NPC power module

PEN8018 – 800V/18A

Three-level Neutral Point Clamped (NPC) converters up to 4kW per module.

H-bridge module

PEH2015 – 200V/15A

Multilevel converters (e.g. MMC) and teaching applications, up to 400W per module.

H-bridge module

PEH4010 – 400V/10A

Multilevel converters (e.g. MMC) and teaching applications, up to 400W per module.

INVERTER MODULES FOR LABORATORY DEVELOPMENTS

POWER MODULES HARDWARE INTEGRATION OPTIONS

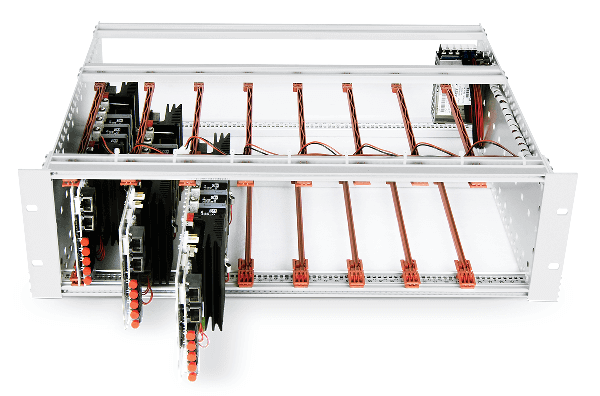

Imperix power inverter modules are best assembled within rack-mountable frames or enclosures. This guarantees the highest flexibility, thanks to the modular nature of the power modules.

FLEXIBLE RACK-MOUNTABLE CHASSIS (3U)

For those who appreciate the corresponding ease of use, imperix can provide pre-assembled chassis with power supplies and various other features. This way, development modules remain easily accessible and can be easily put in (or taken out) of the chassis, hence facilitating topology alterations.

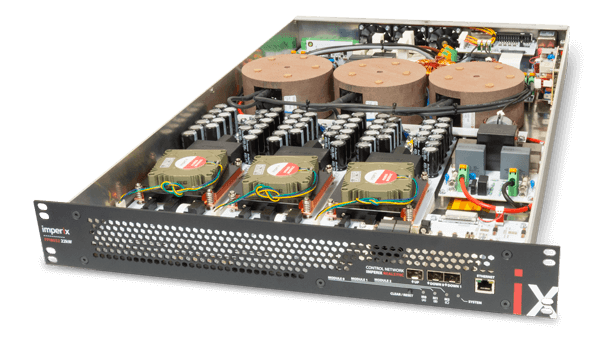

FULLY-INTEGRATED ENCLOSURE (4U)

When an elegant integration of the modules is important, the power inverter modules can also be placed within rack-mountable enclosures. This also guarantees that no dangerous voltage can ever be reached, except using 4mm laboratory safety plugs. In 4U enclosures, an LCD screen displays modules status information as well as internal temperatures.

ALL-IN-ONE-INVERTER (1.5U)

In the specific case of two-level three-phase inverters, the topology covers such a wide range of applications that modularity and reusability of the equipment are not necessarily a concern. Instead, a compact all-in-one solution is more compelling, as it minimizes wiring efforts and can achieve superior EMC performances. The TPI8032 offers a 22kW inverter power stage, including passive filters, relays, voltage/current sensors, and a B-Board PRO embedded controller.

PRE-CONFIGURED POWER MODULES ASSEMBLIES

SCALABLE POWER ELECTRONIC SOLUTIONS

Our laboratory solutions have varying degrees of integration. Indeed, they are available either as bare control hardware and power inverter modules, as pre-assembled systems, or even as fully ready-to-use power electronic test benches.

CONFIGURATION EXAMPLES

Discover our kits and bundles to see typical configurations with our power inverter modules.

HARDWARE + SOFTWARE

HARDWARE + SOFTWARE

HARDWARE + SOFTWARE