Benefits of Hardware-in-the-loop simulation:

- Start control testing early, with real control hardware;

- Pre-validate the control when the power stage is not (yet) available;

- Conduct dangerous or potentially destructive tests;

- Integrate external equipment (e.g. communication) into the test bench, from the start.

HIL SIMULATOR INTERFACES

INTERFACES FOR REAL TIME SIMULATION SOLUTIONS

Imperix offers HIL simulator interfaces for the most well-known real-time simulators, contributing to accelerating the control testing of power electronic converters.

For instance, by interfacing the real control equipment (hardware and software) with emulated power electronic circuits, engineers can easily debug and validate control algorithms, without necessarily building a downscaled system mockup.

Furthermore, when needed, power equipment may also be involved within the control loop(s), hence building so-called Power Hardware-in-the-loop (PHIL) configurations.

REAL TIME SIMULATION OF POWER CONVERTERS

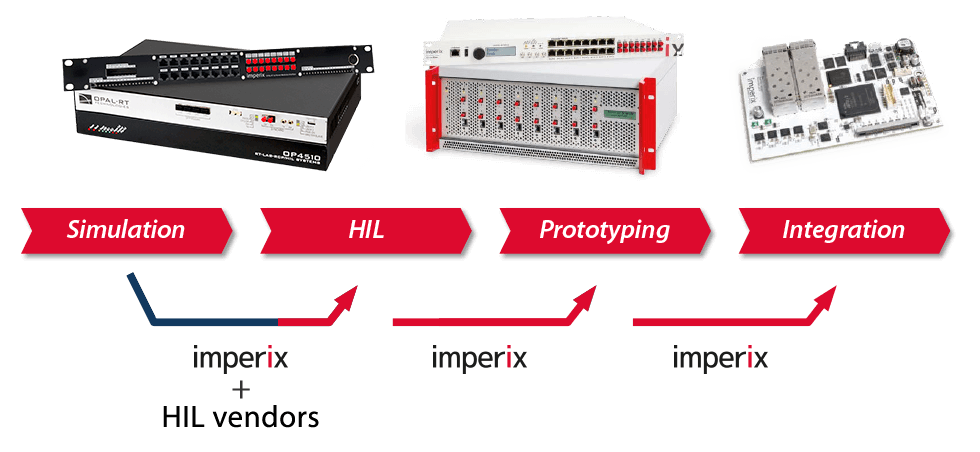

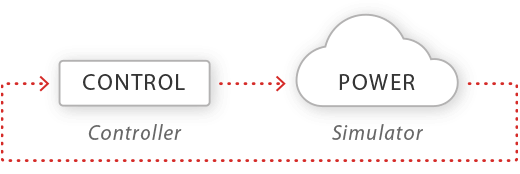

Typical workflow

Both the control and the power stages are simulated on the computer, for instance using Simulink or PLECS. For imperix controllers, accurate models are part of the dedicated ACG SDK.

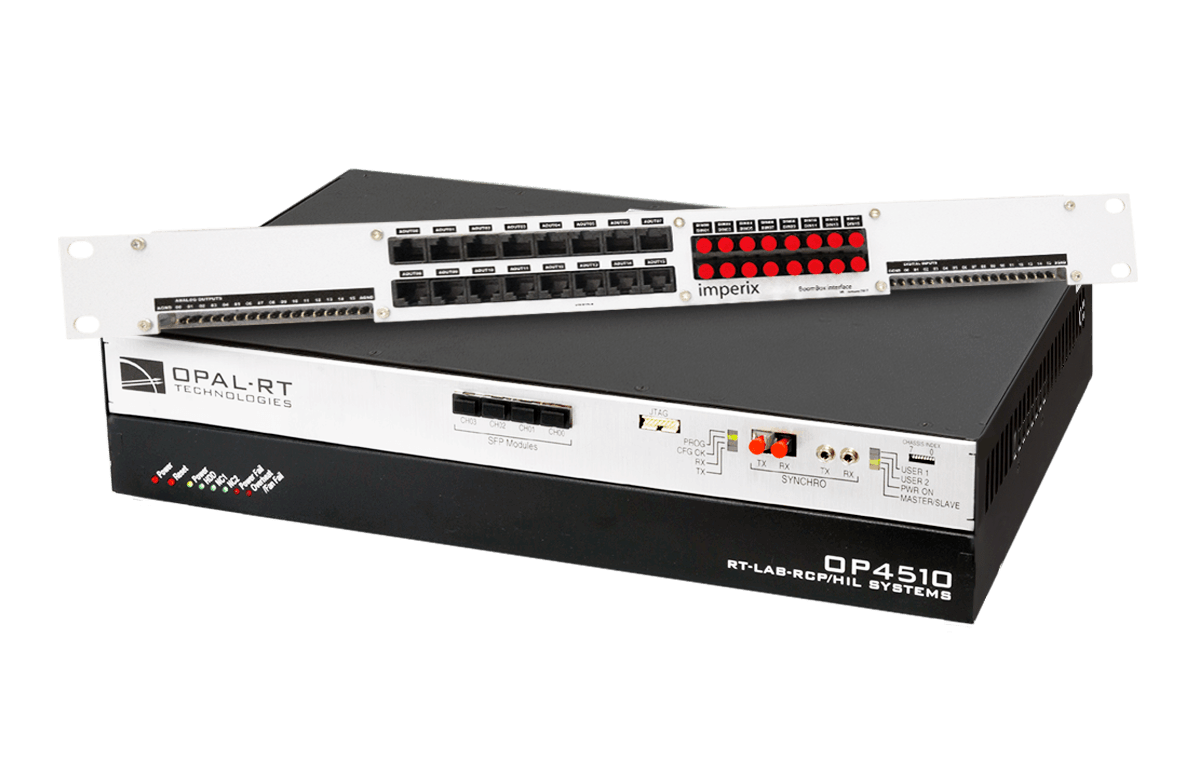

The capability to run simulation models in real-time enables engineers to make simulations interact with real-world equipment. For instance, the control software may be run on a B-Box 4, while the plant model is run in real-time on the FPGA of an OP4510.

Eventually, complementary control validation can be obtained in the laboratory with the real system or a prototype. At this stage, electromagnetic compatibility or system efficiency can also be tested and validated.

Real-time simulation for teaching!

The B-Box family controllers possess the unique capability to protect power electronic equipment, thanks to ultra-fast hardware protections. However, operating power inverters with potentially dangerous voltages always remain non-trivial with students or inexperienced staff.

In such a context, hardware in the loop testing with real-time simulation may be a good alternative to experimental activities. They offer a sufficient level of accuracy for control-related purposes, in a virtually harmless environment.

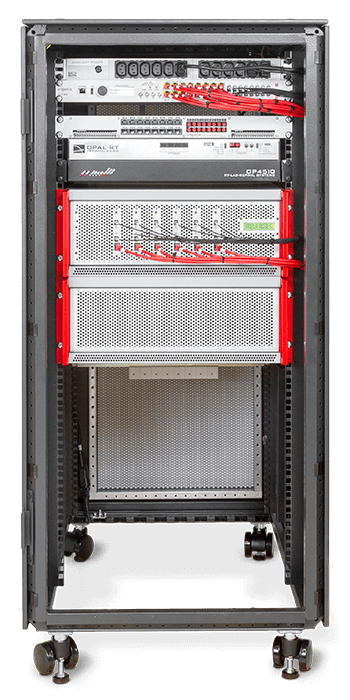

CONTROLLER HARDWARE IN THE LOOP (HIL)

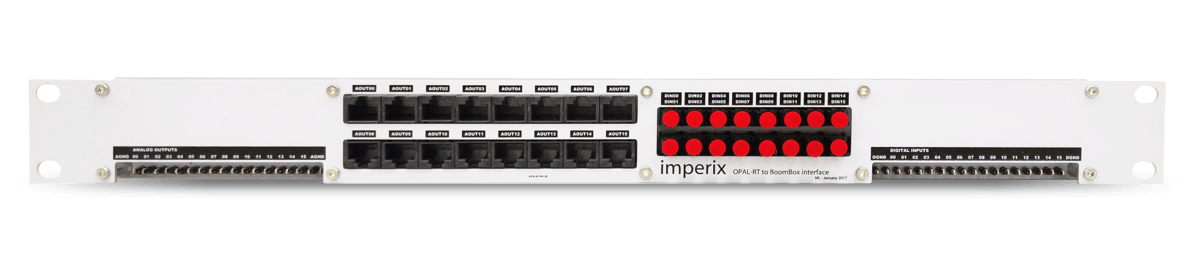

HIL SIMULATOR INTERFACE

THE SIMULATOR INTERFACE INTERCONNECTS THE B-BOX FAMILY TO A THIRD-PARTY HIL SIMULATOR.

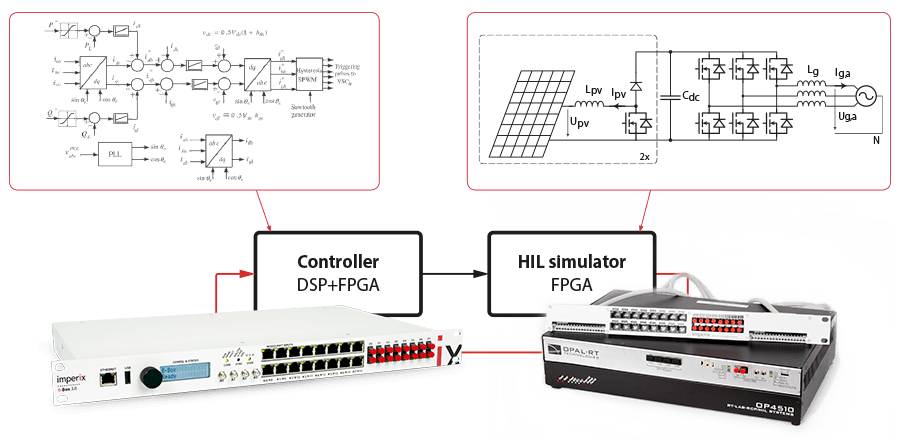

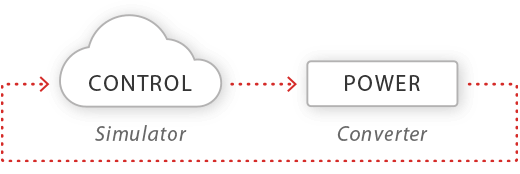

The so-called controller hardware-in-the-loop (or C-HIL) configuration combines the real control system with a simulated power converter. This configuration is often used for control testing before the power stage (or a reduced-scale prototype) is available.

In general, one HIL simulator interface is sufficient, but several units can also be used when numerous I/O signals are needed.

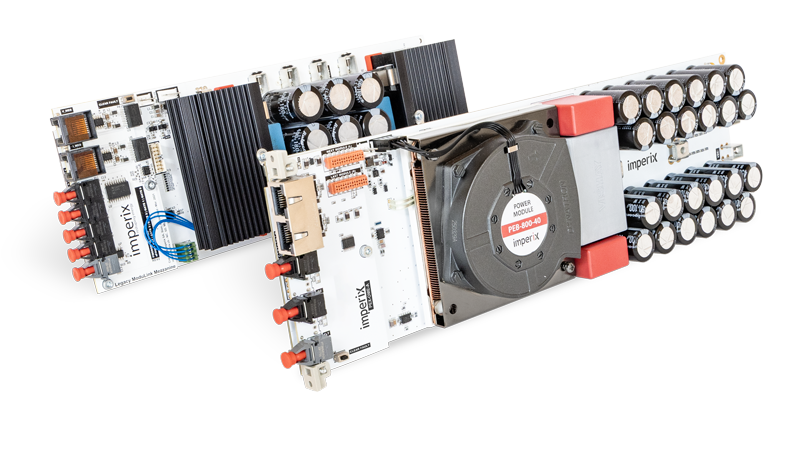

The B-Box 4 and B-Box RCP3.0 are real-time controller that is dedicated to the control of power electronic systems. Its hardware makes it tailored for rapid control implementation in laboratory environments but the unit is also perfectly suitable for industrial use as well.

By connecting the B-Box controller to a real-time simulator, engineers can emulate the power inverter (or any other converter topology) instead of implementing a downscaled version. This can accelerate and facilitate the inverter control testing.

HIL SIMULATOR INTERFACES FOR THIRD-PARTY SIMULATORS

FOR OPAL-RT

FOR TYPHOON HIL

FOR PLEXIM

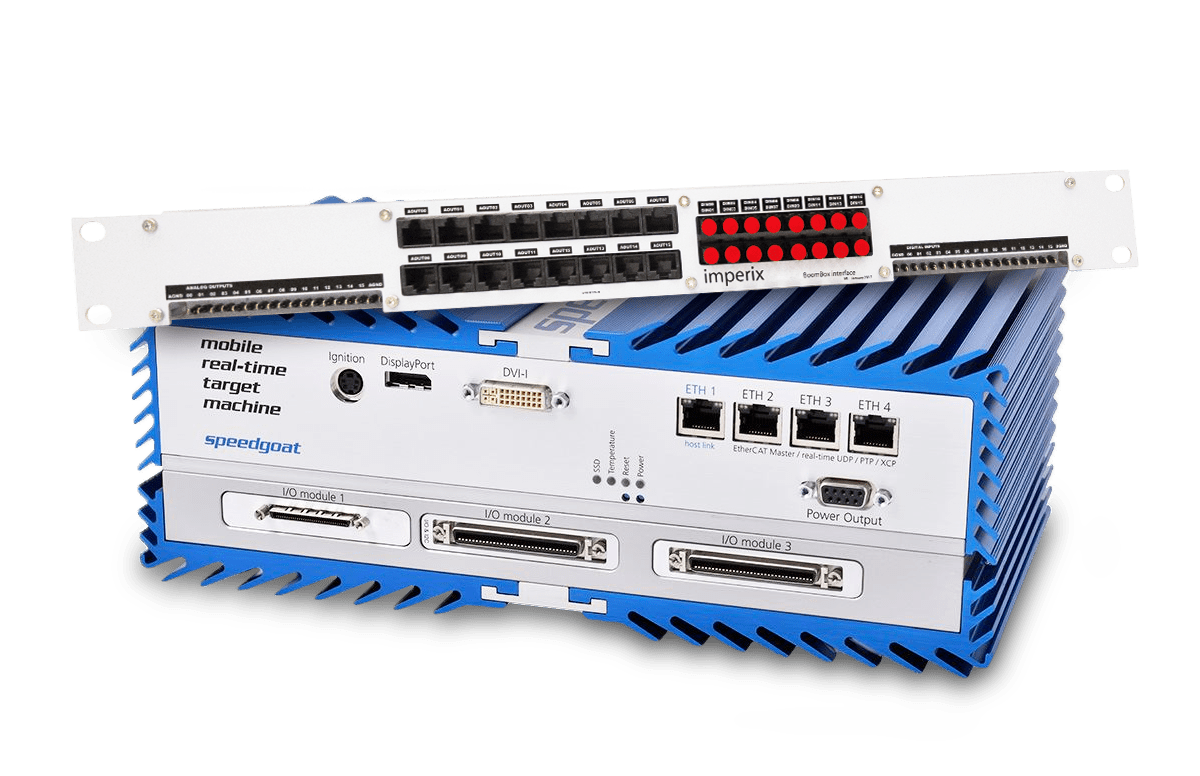

FOR SPEEDGOAT

POWER ELECTRONIC TEST-BENCH

MICROGRID INVERTER SIMULATION AND TESTING

Interfacing with Opal-RT’s HIL simultors

Imperix and Opal-RT have developed a ready-to-use system, which combines equipment from both companies. This product bundle supports real-time simulation and low-voltage prototyping equipment in a single system.

Users only need to swap cables from the HIL simulator interface to the power stage to start experimenting with real power inside their laboratory.

with your models

By working iteratively between real-time simulation and experimental research, the validation of the system model(s) can be made in a straightforward manner.

from the laboratory

Journal publications often require experimental results, which can be a tedious task. With this test-bench, most challenges can be solved using real-time simulation, making the experimental part faster and easier afterwards.

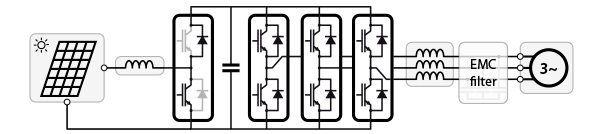

THREE-PHASE PV INVERTER EXAMPLE

Work with a simulated panel to easily control irradiance conditions!

Work with a real PV panel and improve the realism of your setup!

Simulate unbalanced or faulty grid conditions!

Measure real power flows and evaluate efficiency!

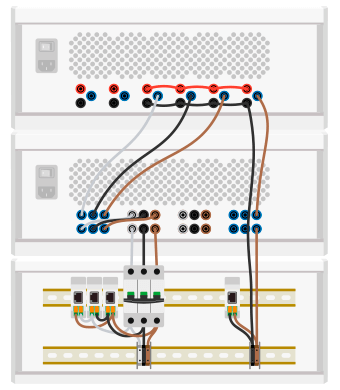

POWER HARDWARE IN THE LOOP (PHIL)

HIL POWER INTERFACES

THE POWER INTERFACE INTERCONNECTS A THIRD-PARTY HIL SIMULATOR TO IMPERIX POWER MODULES.

This interface allows controlling imperix power modules from a real-time simulator. It provides the necessary signal connections to easily wire the digital outputs of the HIL simulator hardware to the command inputs of the power modules, and retrieve any useful measurement to its analog inputs.

The black interface hence differs from the white one in the sense that the HIL power interface is here directly connected to the power stage.

Real-time simulators can obviously not only be used to emulate power circuits but control systems too! As such, owners of a HIL simulator can easily implement power hardware in the loop (PHIL) systems by only adding power modules to their existing equipment.

Our power electronic building blocks allow building real laboratory-scale power converters in a modular fashion. As such, they can easily be involved in various sorts of experimental activities, including PHIL simulation (Power Hardware-in-the-Loop).

INTERFACES FOR IMPERIX MODULES

FOR OPAL-RT

FOR SPEEDGOAT

FOR PLEXIM

TOOLS FOR THE COMPLETE PRODUCT DEVELOPMENT CYCLE

COMPREHENSIVE SOLUTIONS

With the help of third-party HIL vendors, imperix can assist R&D engineers in their efforts to implement HIL and PHIL simulations. What’s more, this can be done – from the start! – with the exact same software and tools as the final product, hence guaranteeing a consistent development environment!

Then, imperix offers ready-to-use prototyping equipment, thereby facilitating and accelerating the experimental testing, again, with the same control hardware and software. Finally, our product-embeddable controller guarantees a seamless integration into the final product.