SOLUTIONS FOR

THE INDUSTRY

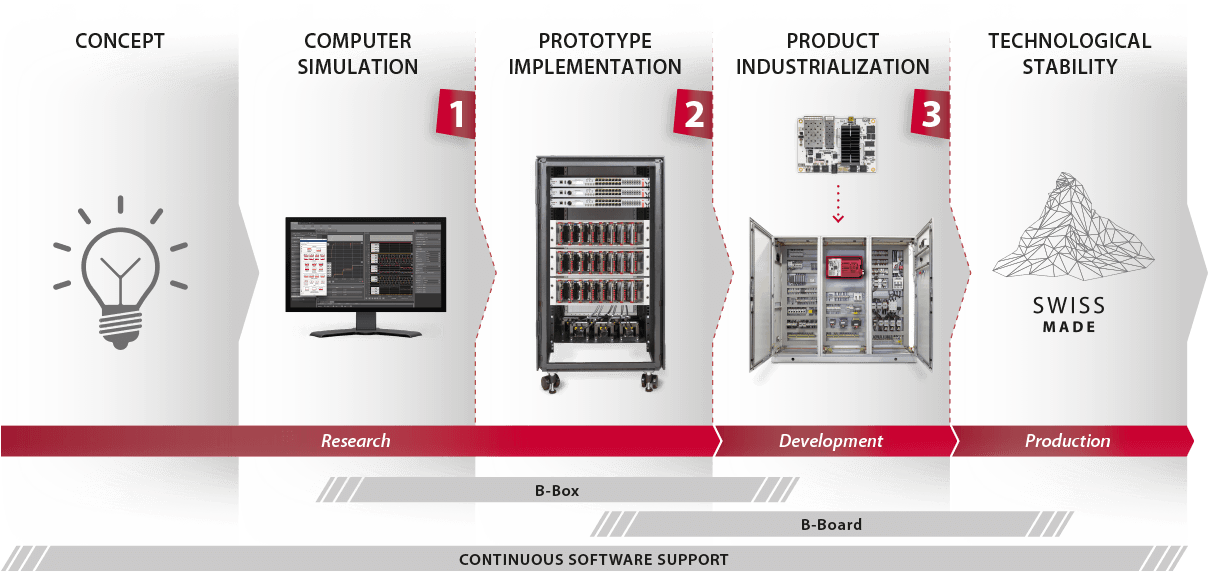

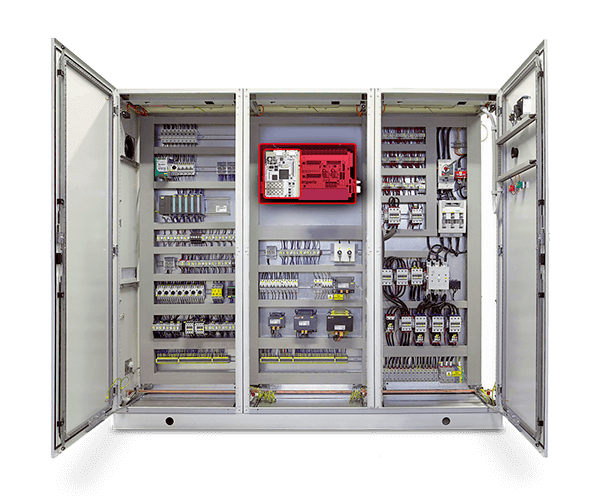

Imperix offers a complete family of control solutions, supporting the whole life cycle of power conversion systems, from R&D to commercial products.

These solutions alleviate the various challenges occurring in-between the different steps of the product design, contributing to significantly reduce the time to market as well as mitigate design risks.

COMPREHENSIVE SOLUTIONS

Tools for the whole product life cycle!

Lower time to market

With solutions for both the prototyping phase and the product integration phase, imperix enables its customers to truly accelerate the path from R&D to commercialization, minimizing the overall time to market.

Lower Risks

Rapid control prototyping allows to evaluate the feasibility of design ideas quickly and thoroughly. Besides, by going to the lab early, possible implementation issues are identified swiftly, contributing to reduce project risks.

Easier Maintenance

The maintenance of control hardware and software can be a painful task, especially when resources could preferably be allocated elsewhere. Imperix products guarantee up-to-date performance and long-term stability.

FROM THE COMPUTER TO THE LAB

Bridge the gap between the simulation and the real world!

Accurate simulations are guaranteed, thanks to a perfect functional equivalence between B-Box 4, B-Box RCP 3.0 and B-Board PRO3.0, as well as to a precise modeling of the discrete-time control during simulation.

Instant switchover between simulation and experimentation is possible in just one click. This allows to move very quickly to the lab, or even work iteratively to improve the simulation model.

Early experimentation is possible, thanks to the software-independent protections of the B-Box 4 and the B-Box RCP 3.0. This enables to identify potential challenges early and mitigate implementation risks.

No controller tuning is ever needed thanks to the seamless transition between the simulation and the real world. The same also applies between B-Box RCP 3.0 and B-Board PRO3.0, which are 100% bitfile-compatible.

What if you could simply take the result of your research and put it into an affordable controller, directly embeded inside your own products?

FROM THE LAB TO THE FIELD!

DEVELOPMENT PHASE

- Flexible hardware

- Rapid control validation

PRODUCTION PHASE

- Cost-optimized hardware

- Product integration

Prototyping controller

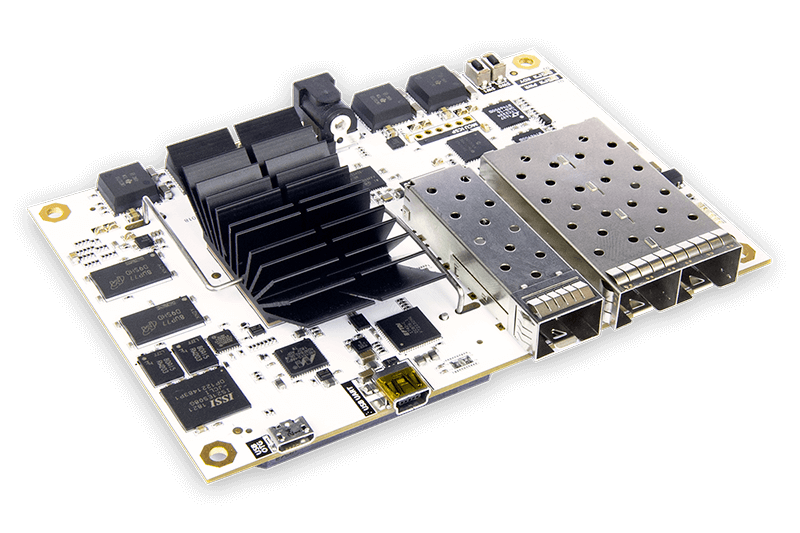

The exact compatibility between B-Box RCP 3.0 and B-Board PRO power electronic controllers allows benefiting from the increased flexibility of the prototyping controller during development, while using a product-embeddable variant during series production.

Embeddable controller

Bitfile compatibility

The FPGA-based abstraction layer present in B-Box RCP 3.0 and B-Board PRO guarantees the exact same performance (especially timings) on both devices.

Small form factor

Despite its numerous I/Os, the B-Board PRO measures only 86×124 mm. This is small enough to be assembled in most industrial control systems.

Processing power

The 3rd generation of controllers are based on dual-core processors and modern FPGAs for best performance in demanding applications.

MAINTENANCE

Let us take care of the maintenance of your control solution!

Digital control electronics suffer from a shorter life cycle than their associated power stages. This may be challenging for companies that have limited resources devoted to their maintenance. The same remark also holds to the software development tools.

Relying on imperix’s solutions avoids this burden and guarantees to work with up-to-date hardware and software at all times, for both prototyping and embeddable solutions.

Thanks to a strict abstraction from the hardware resources and strong retro-compatibility guidelines, imperix also guarantees that any control code will still work on future equipment.