Table of Contents

This document introduces the two variants of the closed rack (Type C and D). Designed to assist first-time users, the guide details the auxiliary power supply requirements, the wiring process, and messages displayed on the LCD screen.

Alternatively, modules may be housed in an Open rack. This configuration offers more flexibility, allowing users to mix several types of modules and easily swap units.

What is inside a closed rack?

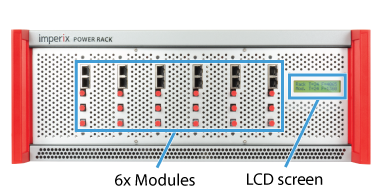

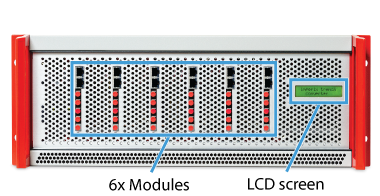

A closed rack is a metallic frame designed to house either six or eight imperix power modules. It consists of:

- Six or eight slots equipped with plastic mounting rails to hold power modules.

- An LCD screen to display status information.

- Integrated cooling fans for the rack.

- An auxiliary power supply for the power modules, the screen, and the fans.

A closed rack type C houses either six or eight identical PEB modules. Compatible imperix products are listed in the table below.

| Module | Topology | Status | Alternative rack |

|---|---|---|---|

| PEB-800-40 | SiC half-bridge | Active | Open rack type A |

| PEB8024 | SiC half-bridge | NRND | Open rack type A |

| PEB8038 | SiC half-bridge | NRND | Open rack type A |

| PEB4050 | IGBT half-bridge | NRND | Open rack type A |

Similarly, the closed rack type D houses either six or eight PEN modules.

| Module | Topology | Status | Alternative rack |

|---|---|---|---|

| PEN8018 | NPC phase-leg | Active | Open rack type A |

Auxiliary power supply

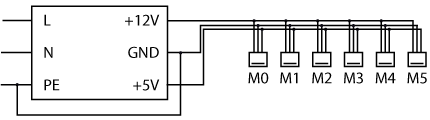

A dual-output power supply energizes the auxiliary circuits for all six modules, as illustrated below. The +12V output is dedicated to the fan and gate drivers, while the +5V output powers all remaining components. For racks containing eight modules, two additional connectors are included to accommodate the expanded capacity.

Closed racks were originally equipped with a Delta Electronics PMT-D1V100W1AA power supply. To accommodate the higher power requirements of PEB-800-40 modules, this was upgraded to a Mean Well ADS-15512 in early 2026. The specifications of both models are summarized in the following table:

| Specifications | PMT-D1V100W1AA | ADS-15512 |

|---|---|---|

| Output voltage (CH1) | +12 V | +12 V |

| Rated current (CH1) | 7 A | 11.5 A |

| Output voltage (CH2) | +5 V | +5 V |

| Rated current (CH2) | 3 A | 3 A |

| Rated power | 100 W | 153 W |

| Input voltage range | 100 ~ 120 VAC or 200 ~ 240 VAC | 100 ~ 240 VAC |

| Input frequency range | 47 ~ 63 Hz | 47 ~ 63 Hz |

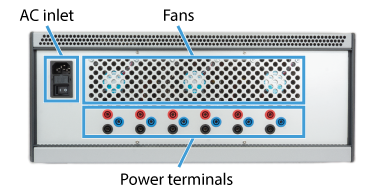

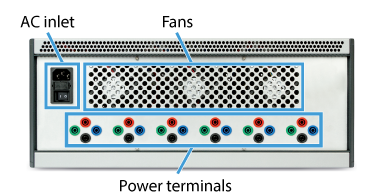

The AC inlet includes two 2A / 250V ceramic fuses (Bel 5HT 2-R) in a tray, as shown below. The left one is connected in series to the AC input to protect the auxiliary power supply, while the right one is a replacement unit.

Wiring the power modules

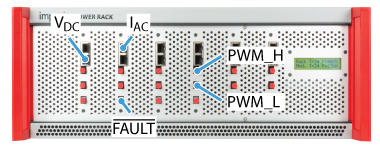

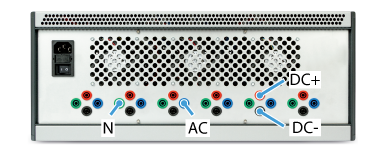

Closed rack type C

Using the power modules necessitates wiring on both the power and control sides. For this purpose, users are provided with the following elements:

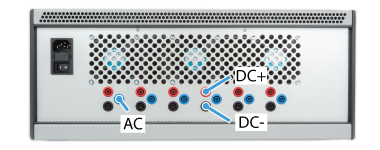

- The switching node (AC).

- The positive (DC+) and negative (DC-) DC bus terminals

- Two analog outputs for the on-board sensors IAC and VDC (RJ-45 sockets).

- Two optical inputs for the high (H) and low (L) PWM gating signals.

- An optical fault output.

The integrated sensors do not utilize the Ethernet protocol for data transmission; rather, RJ-45 cables are capable of conveying analog signals due to their shielding and twisted-pair construction. A dedicated ±15V external supply is required for each onboard sensor, delivered through the RJ-45 cable. B-Box controllers provide this voltage. However, third-party controllers may necessitate an independent power source.

Gating signals are sent through standard 650 nm Plastic Optical Fibers (POF) or Plastic Clad Silica (PCS) fibers. No special coding is required: light ‘ON’ applies a positive voltage on the gate; light ‘OFF’ applies a negative one. Similarly, the optical fault output is in the light ‘OFF’ state to indicate a fault condition. This signal is retrievable by B-Box controllers utilizing an Optical Expansion Board.

Finally, the power stage is wired with 4 mm safety (banana) plugs.

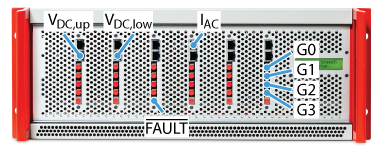

Closed rack type D

Type D racks provide a slightly different connectivity:

- The switching node (AC).

- The DC bus positive (DC+), negative (DC-), and mid-point (N) terminals.

- Two analog outputs for the on-board sensors IAC and VDC (RJ-45 sockets).

- Four optical inputs for the PWM gating signals (G0 to G3).

- An optical fault output.

Each PEN measures both upper and lower DC bus voltages, but outputs a single value based on a jumper configuration. More information about this jumper is provided in the Open rack – Quick start guide. In a closed rack type D, jumpers are not user-accessible; consequently, modules output upper and lower DC bus voltages alternately, starting with the upper voltage.

Status information and fault signaling

Modules are interconnected in a daisy-chain configuration via ribbon cables to enable global fault propagation and centralized fault clearance. This communication bus also transmits real-time status information—including fan speeds, temperatures, and fault flags—to the LCD screen.

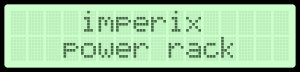

Booting and normal operation

When a closed rack is turned on, the LCD displays a booting message for 1 second:

After the boot, the screen displays the following information:

- The temperature inside the rack [°C]

- The highest fan speed of the three fans at the rear of the rack [rpm]

- The highest temperature among all the power modules [°C]

- The highest fan speed of all the power modules [rpm]

As long as there are no faults, the screen is refreshed every second.

Behavior under fault

Each module can generate any of the following local faults, immediately blocking the gating signals:

| Flag | Description |

|---|---|

| V. | Over-voltage detected on the DC bus, or DC bus imbalance |

| I. | Over-current detected at the switching node (AC) |

| T.F | Over-temperature on the cooler, or probable fan fault (no tachometer signal) |

| P. | Inadequate power supply voltage |

| D. | Excessive drain-source voltage during on-state*, or 1-1 condition detected on the PWM signals |

* only for PEB modules

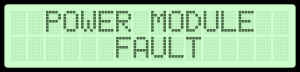

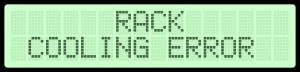

Detailed fault diagnostics are available on the LCD screen, and error messages will cycle continuously until the fault condition is resolved:

- A first message indicating the source of the fault. The possible sources are:

- “POWER MODULE FAULT” if the fault comes from one of the modules,

- “RACK COOLING ERROR” if there is an issue with the enclosure’s fans or the internal temperature probes.

- Subsequently, the system displays a sequence of six or eight status messages (one per module) to identify local faults. If a fault is detected, the specific error type is reported. If the module is functioning correctly, the display provides real-time operating temperature and fan speed metrics.

- The last message displays the highest temperatures and fan speeds, as in normal operation:

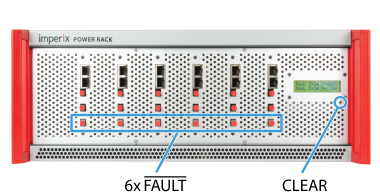

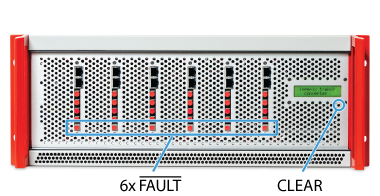

The integrated logic generates a global fault indicator, which is made available via an optical output (see below) and propagated to the other modules. Also, fault clearance is performed by actuating the dedicated clear button, which is located below the screen.

Going further with the closed rack…

A fully functional converter requires a controller, such as the B-Box 4, in addition to power modules. The following articles provide all the necessary information to build a complete converter with a closed rack.