Table of Contents

This page explains how to get started with the TPI 8032 all-in-one programmable inverter. It provides an overview of the hardware architecture and detailed instructions to program the device.

An open-loop voltage-source inverter example with passive loads is provided as a demo example for the TPI 8032, with a step-by-step operation procedure for users to become familiar with the product.

What is the TPI 8032?

The TPI 8032 is an all-in-one product that integrates all the necessary components for running a two-level three-phase inverter, covering from the digital controller to the power stage. The typical applications include grid-tied inverters, back-to-back converters, etc. Thanks to the imperix RealSync proprietary technology, multiple TPIs can work together or with other imperix controllers in various setups, covering almost any converter topology.

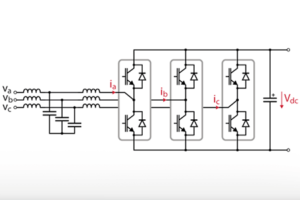

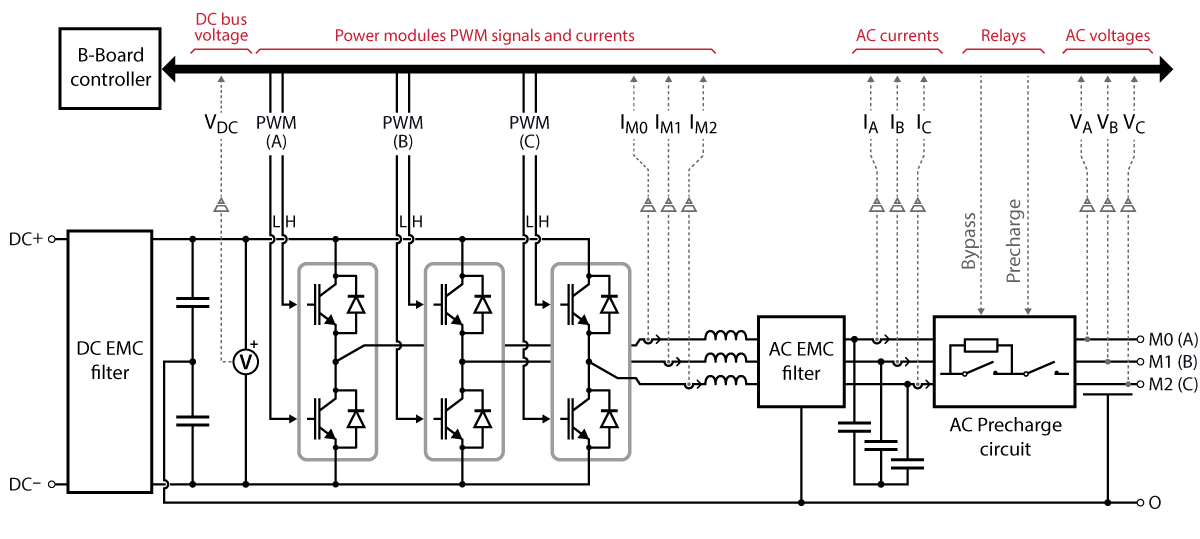

The power stage of the TPI 8032 is a three-phase inverter made of three half-bridge power modules based on Silicon Carbide (SiC) MOSFETs with one inductor at each phase output. Two EMC filters are placed on both sides of the inverter to reduce the electromagnetic interferences (EMI) generated by the switching devices (refer to the datasheet for detailed information on the EMC filters).

The control stage of the TPI 8032 is built with a B-Board PRO and a carrier board that collects the sensor inputs and distributes the PWM signals to the power modules.

The TPI 8032 has numerous embedded current/voltage sensors for various uses. The currents flowing through the power modules \(I_{m,0,1,2}\) and the DC bus voltage \(V_{dc}\) are measured on the modules, with over-current and over-voltage protection that protects the device against possible damage. Besides, it also has three-phase current and voltage sensors after the AC EMC filter providing AC-side current \(I_{a,b,c}\) and voltage \(V_{a,b,c}\) measurements.

In the case of grid-connected operation, the DC bus voltage must be higher than the rectified AC voltage. For this purpose, TPI8032 has an integrated AC precharge circuit that enables automated and secured precharge of the DC bus from the grid.

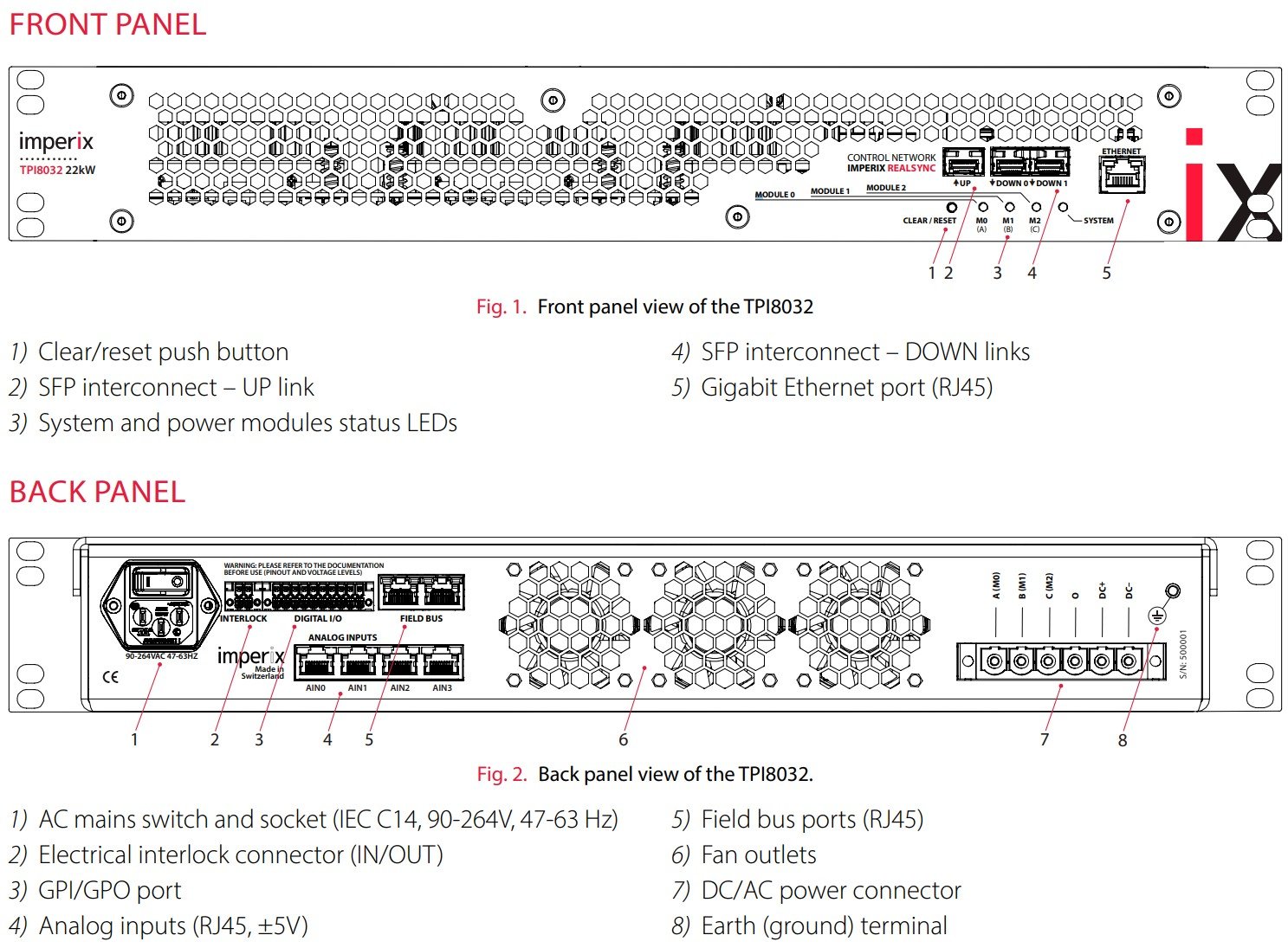

The figure below shows the front and back panels of the TPI 8032. The internal power circuit is accessible from the back panel’s DC/AC power connector. Besides this, the TPI 8032 also has various external ports for control and communication.

In addition to all the internal embedded sensors, the TPI 8032 also has 4 analog inputs for external sensors accessible through the RJ45 connectors on the back panel. These inputs are compatible with the imperix DIN 800V voltage sensor and DIN 50A current sensor.

As for communication, the TPI has SFP interconnect ports that enable ultra-fast communication between imperix controllers with the imperix RealSync proprietary technology. It also supports other widely-used communication protocols, such as CAN and UART, through the two field bus connectors. Please refer to the datasheet for detailed information on all the port functions and parameters.

How to program the TPI 8032?

The TPI 8032 can be programmed either in C++ or with Automated Code Generation (ACG) tools from Simulink and PLECS. The programming procedure is identical to the B-Box RCP and the B-Board PRO.

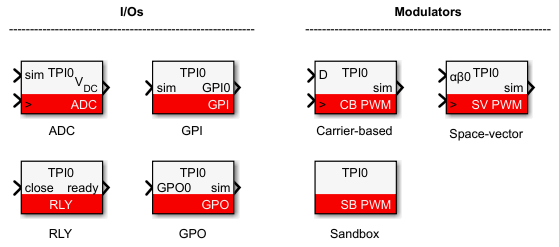

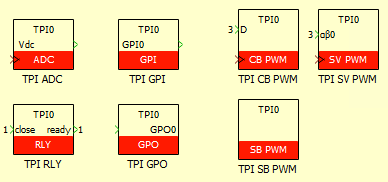

The TPI shows better ease of use regarding wiring and programming than the combination of B-Box RCP and power modules. The hardware circuits have been wired inside the chassis and are easily accessible through the dedicated helper blocks in Simulink and PLECS, which can be found in the sublibrary named TPI of the imperix blockset.

The helper blocks are used similarly to any other imperix blocks but hide the hardware layer and provide only information relevant to the control, such as the dedicated ADC and PWM channels, fixed sensor sensitivities, sensor offsets in Volt/Amp, etc. More details can be found on the following software documentation pages:

It’s important to mention that the helper blocks are not mandatory for programming the TPI. The hardware resources on the TPI are still accessible using the generic imperix blocks such as ADC and CB-PWM as long as the configurations are made correctly as mentioned in the datasheet. However, it’s strongly recommended to use the helper blocks since they are much simpler to use and less prone to configuration mistakes. Besides, the TPI RLY block is necessary for the AC precharge circuit because there is no functionally equivalent block in the generic imperix blockset.

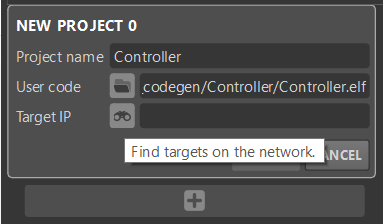

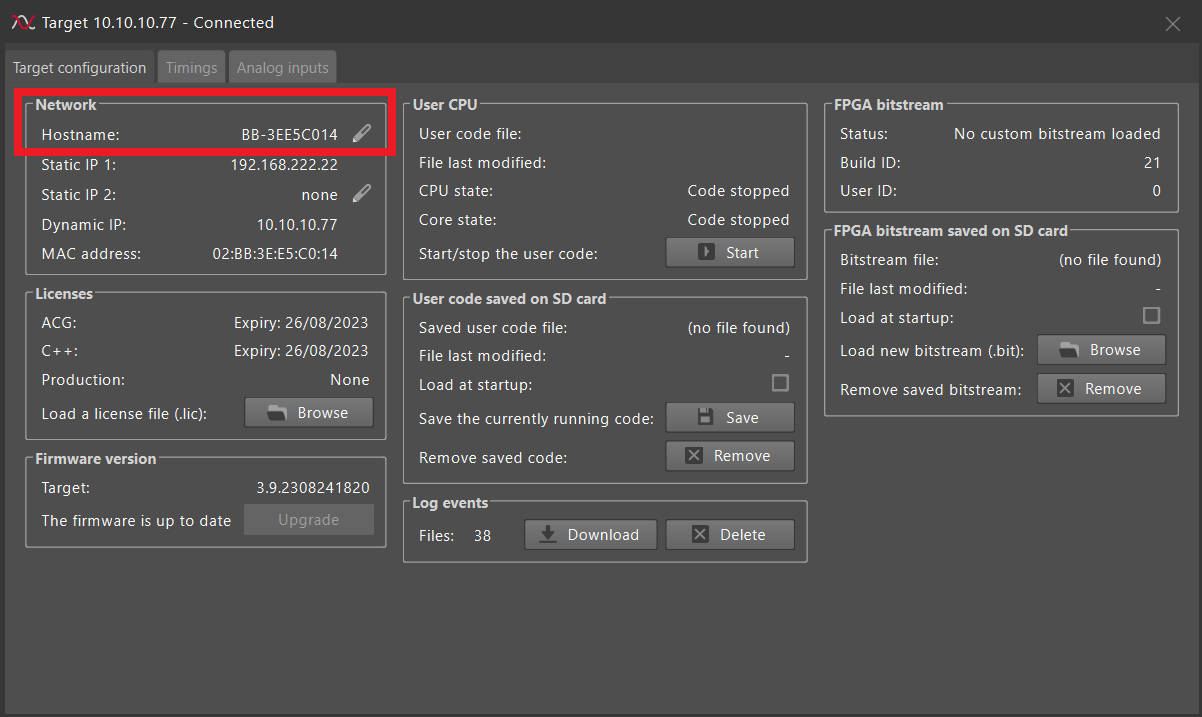

The C++ code or model must first be built before it can be deployed onto the controller. Once the user program is built, regardless of the workflow, Cockpit will automatically launch and create a new project with a pre-filled project name and executable file path. To load the user code (.elf file) to the target and start the code execution, enter the IP address of the TPI and click Create.

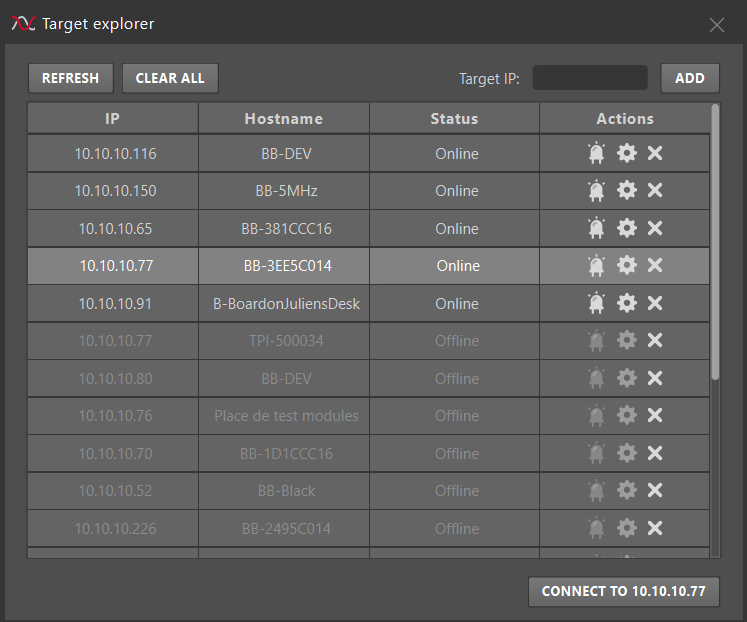

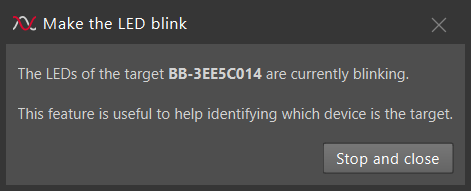

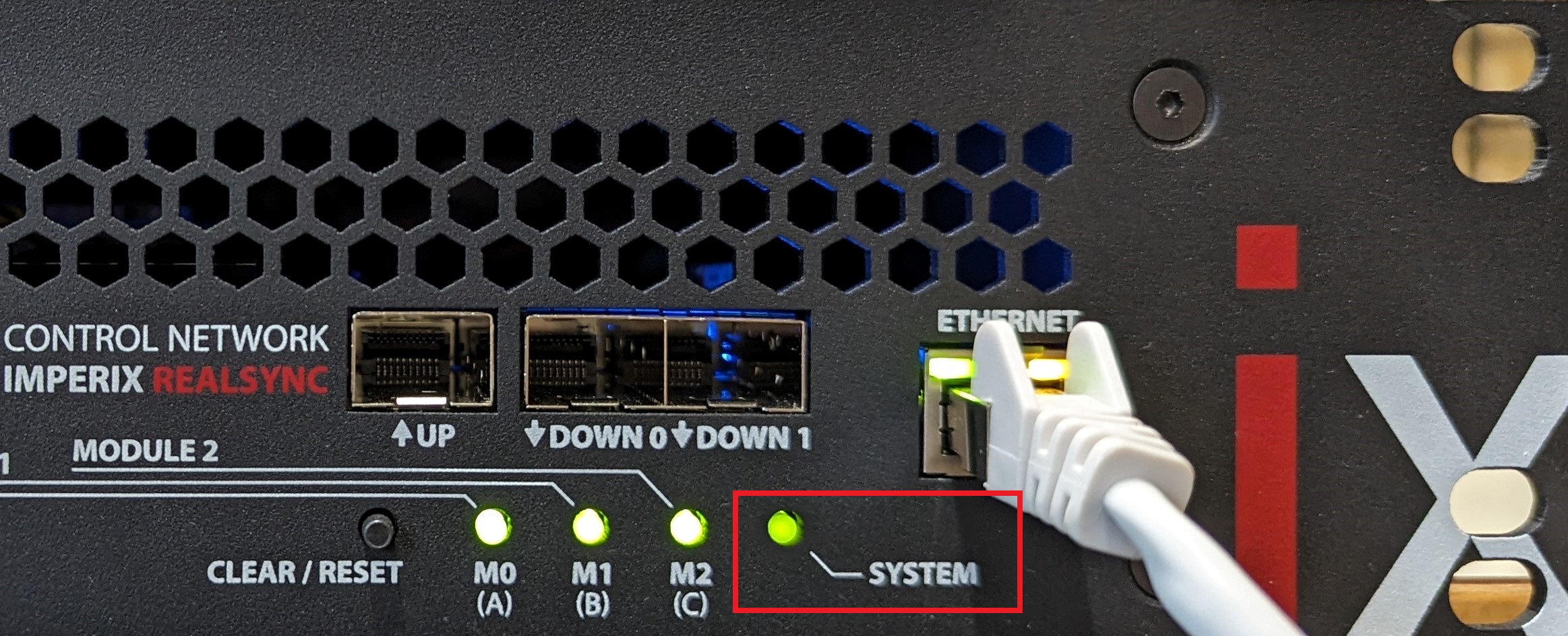

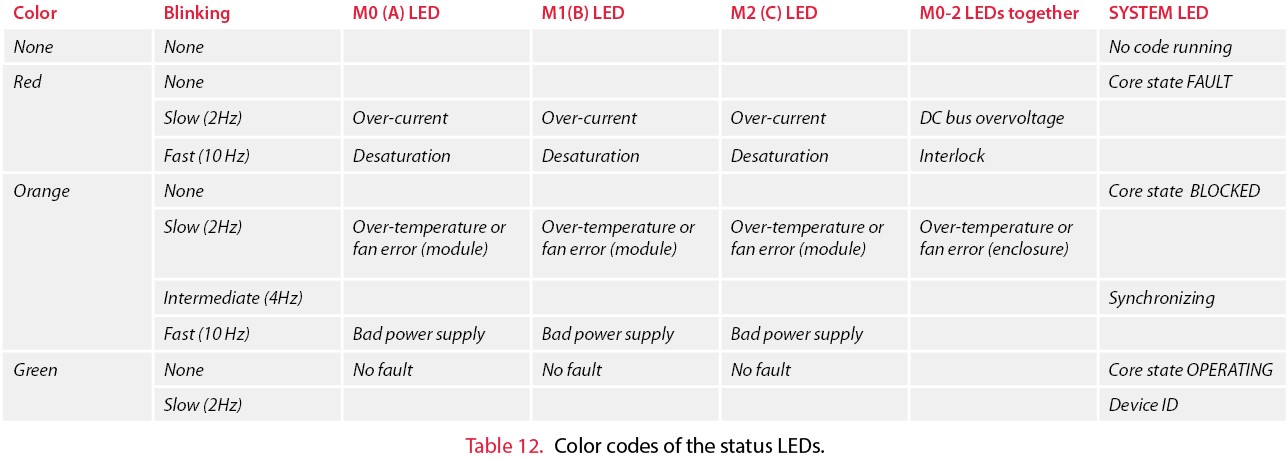

The ethernet connection to the host PC and IP address configuration can be done similarly to the other imperix controllers using the default static IP address 192.168.222.22. However, it might be tricky to identify which device is the target to be programmed, especially when multiple controller devices are in the local network. With the help of the LED blinking function of Cockpit, it’s easy to identify the correct target. The detailed procedure is listed in the pane below.

Instructions for safe use

Although TPI8032 has numerous built-in protections to ensure its safe operation in an experimental environment, it is still essential to follow the safety recommendations when working in the lab. Additionally, the following tabs outline the special precautions to take when working with TPI8032.

Demo example for the TPI 8032

ACG SDK 2024.2 or a later version are required to run the demo example. To update the ACG SDK and Cockpit, please go to imperix.com/downloads/.

The required equipment for running the first test is listed below:

- 1x TPI 8032 three-phase inverter

- ACG SDK toolbox for automated generation of the controller code from Simulink or PLECS

- 1x DC power supply (50V to 800V)

- 3x power resistors (5Ω to 100Ω). The current rating depends on the DC voltage.

- All the necessary cables

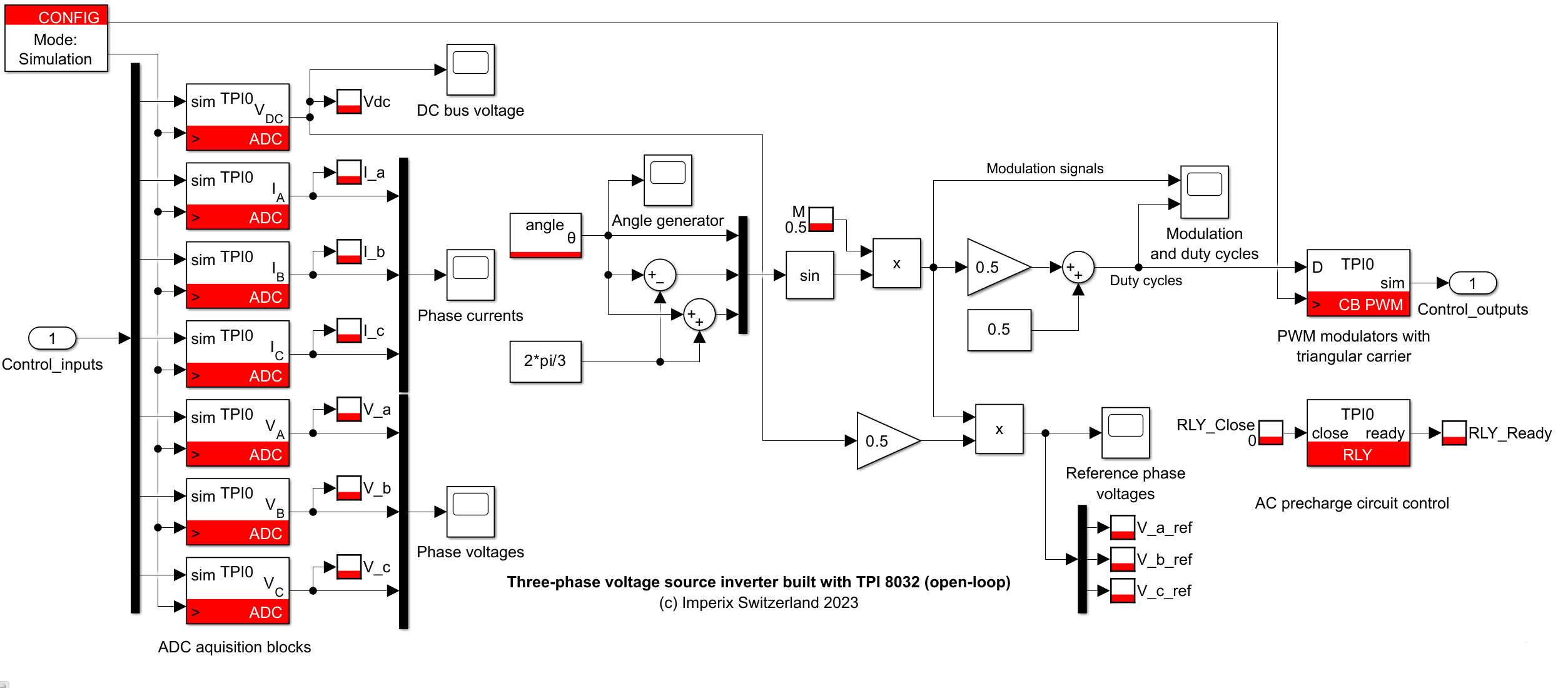

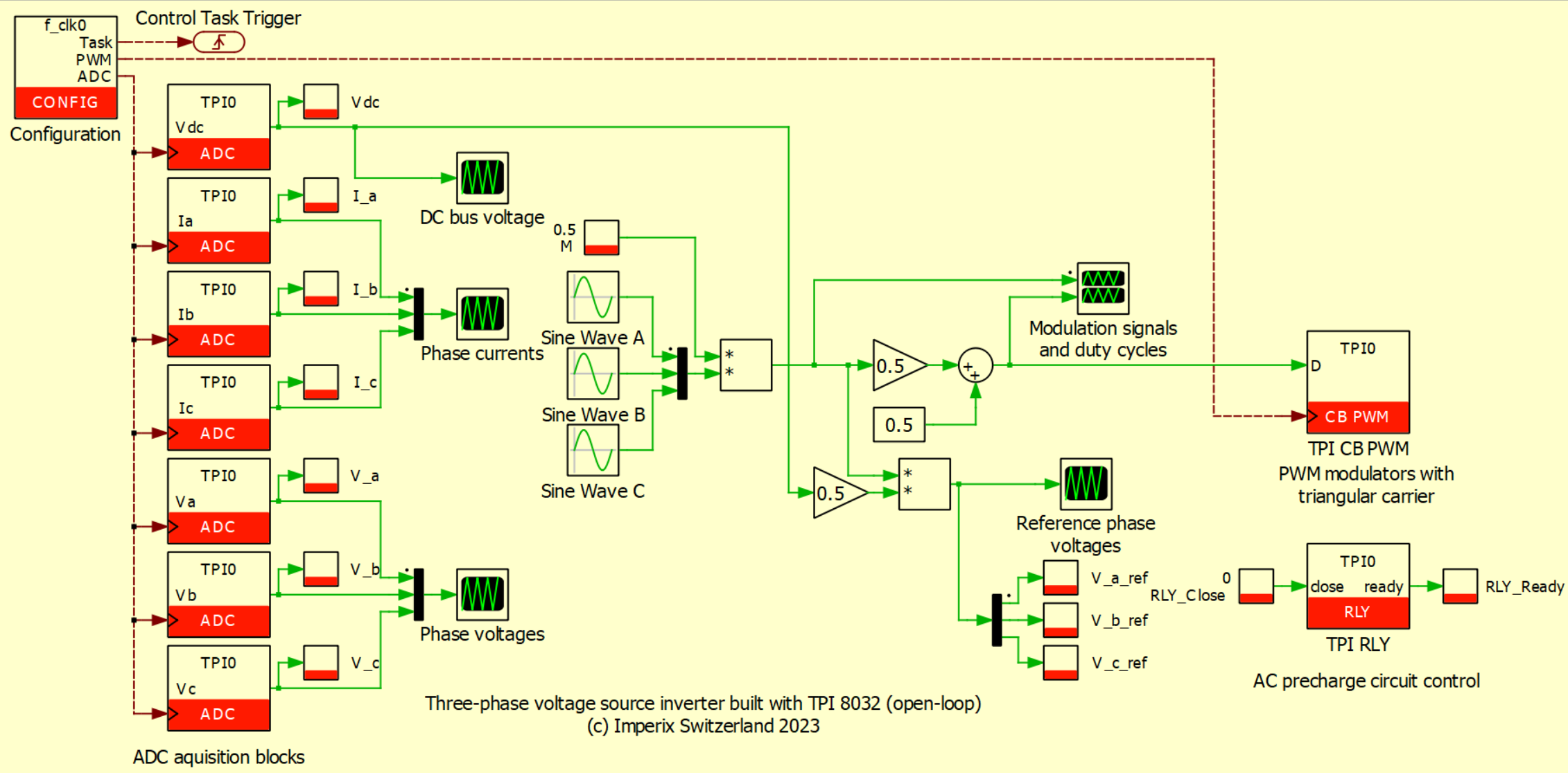

The Simulink and PLECS model provided below implements a three-phase voltage source inverter with passive loads. The phase voltage is controlled in an open-loop manner with a tunable modulation index \(M\).

Passive components sizing

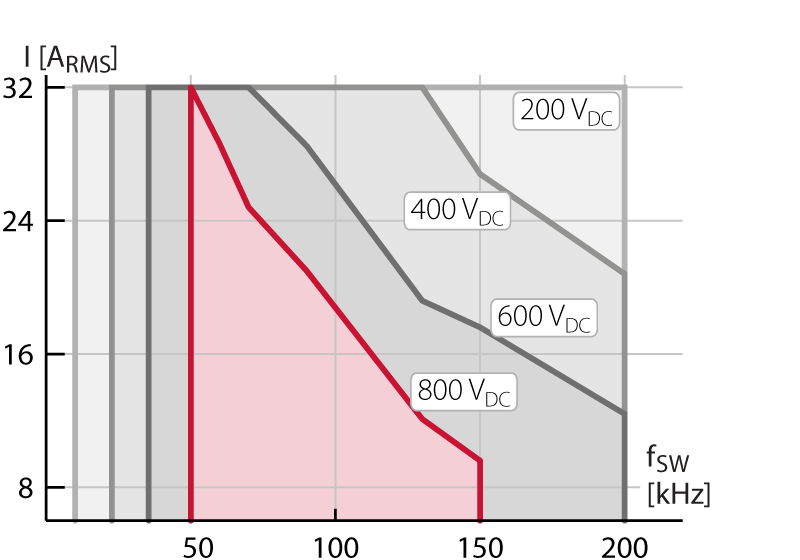

The TPI 8032 has a 0.95mH inductor at each phase-leg output. Considering the operating conditions of the inverter, a DC bus voltage of 200 V and 3x 8.5Ω resistive loads guarantee a maximum output current of 8.3 A with a modulation index of 1. This is confirmed by the formula for the load current from the TN152 :

\(I_{RMS}(M = 1) = \frac{\sqrt{2}}{4} \frac{V_{dc}}{\sqrt{R^2 + (2\pi fL)^2}} = 8.3\,\text{A}\)

| Chosen values | Suggested values | |

| DC Bus | 200V | 50-800V |

| Inductors | 0.95mH | Fixed value |

| Resistors | 8.5Ω | 5-100 Ω |

To ensure safe operation during this demo test, we suggest selecting \(V_{dc}\) and \(R\) such that \(I_{RMS}\) is always smaller than the current ratings of the TPI and the resistors even with modulation index \(M=1\).

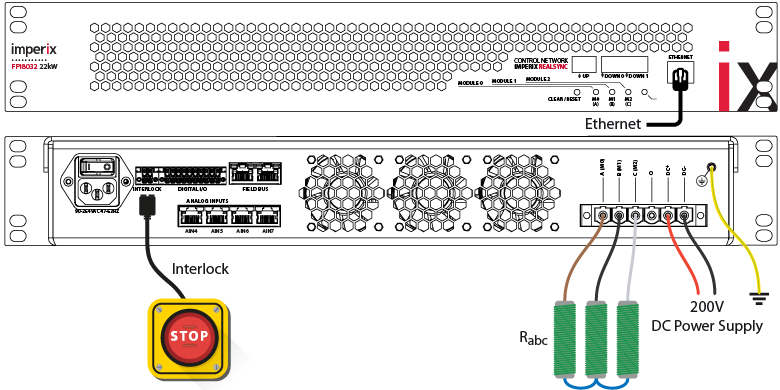

Wiring of the TPI 8032

Starting from the front panel of the TPI8032, connect the ethernet port to the computer’s local network or directly to the PC. Then, on the back panel of the TPI8032,

- Connect the Protective Earth (PE) terminal to the ground.

- Connect the DC- and DC+ terminals to the DC power supply. Double-check that the DC polarity is correct.

- Connect each AC terminal A, B, and C to one of the resistors, and then connect three resistors in a star configuration.

The figure below shows the complete wiring of the TPI 8032.

Building the model with ACG tools

… in Simulink

- Open the Simulink model. Open the Controller subsystem and set the mode to Automated Code Generation in the CONFIG block.

- Build the model (Ctrl + B). It will automatically launch Cockpit.

… in PLECS

- Open the PLECS model. Check the CLOCK_0 frequency is set to f_clk0 in the CONFIG block. The definition of the variable f_clk0 can be found in Simulation -> Simulation parameters (Ctrl + E) -> Initialization.

- Open the Coder Options menu by selecting Coder -> Coder options… (Ctrl + Alt + B). In the General tab, set the Discretization step size to 1/f_clk0. This ensures that the main interrupt rate is set to 1/f_clk0.

- Click on the Build button to build the model. It will automatically launch Cockpit.

Setting up the workspace in Cockpit

- Set the Target IP in Cockpit and click on Create to generate a new project. Use the LED blinking function to identify the target device if needed.

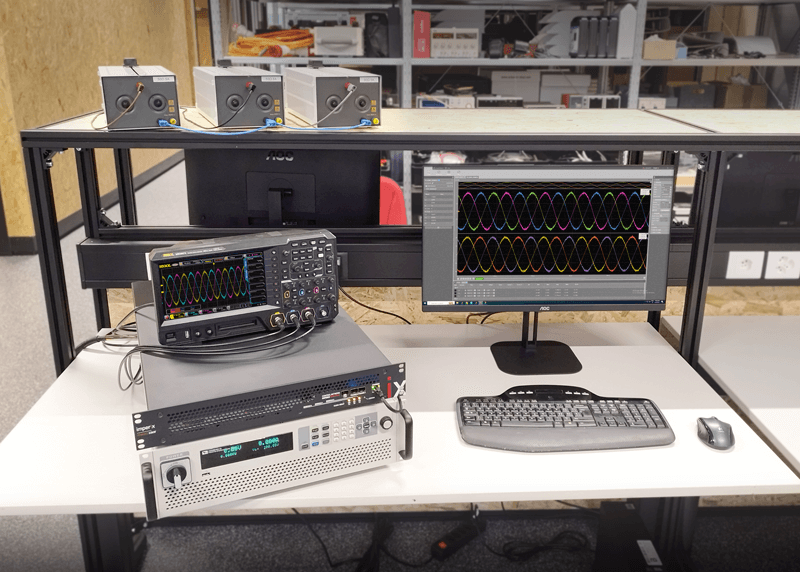

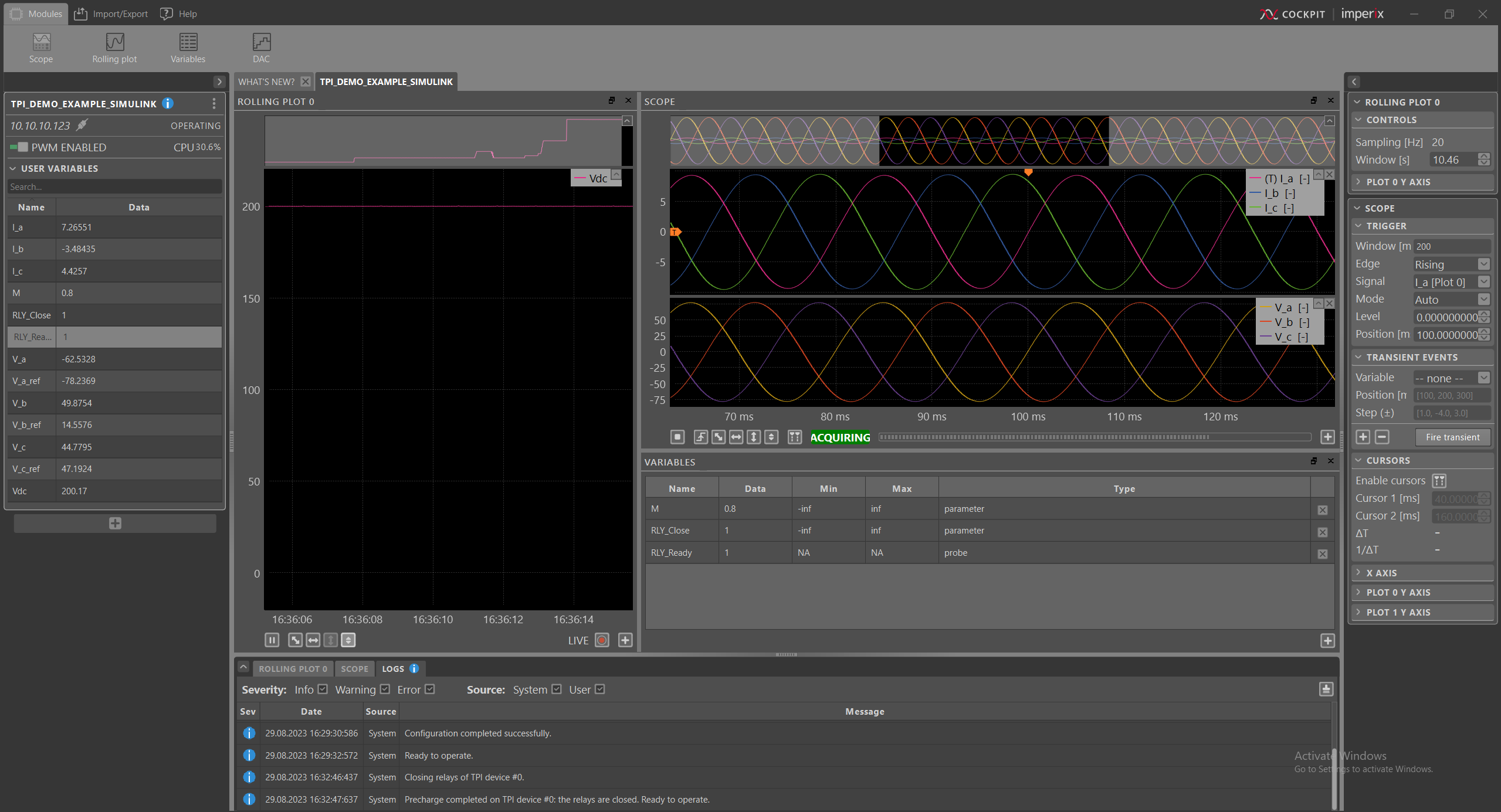

- Add a new rolling plot module and drag-&-drop the Vdc variable to monitor the DC bus voltage. The rolling plot allows for monitoring the DC bus voltage over a long period.

- Add a new scope module and drag-&-drop the I_a, I_b, and I_c variables. The scope can display every sample made available to the control.

- Add a new subplot to the scope module by clicking the ‘+‘ at the bottom right and drag-&-drop the V_a, V_b, and V_c variables.

- Add a new variables module and drag-&-drop the RLY_Close, RLY_Ready, M variables. This way, the main parameters are easy to find.

Step-by-step test procedure

- Ensure the relays are open by checking that the RLY_Close variable is set to ‘0’.

- Turn on the laboratory DC source and gradually increase the DC bus voltage from 0 to 200V. Check with Cockpit that Vdc matches the voltage of the source.

- Close the relays by setting the RLY_Close variable to ‘1’. Check that the RLY_Close goes to ‘1’, which indicates the relays are closed and ready to operate.

- Check that M = 0.5. Enable the PWM outputs from Cockpit and check the peak value of V_a, V_b, V_c by \(V_{a,b,c,peak}=\frac{M}{2}V_{dc}\). Check the peak value of I_a, I_b, I_c by \(I_{a,b,c,peak}=\frac{V_{a,b,c,peak}}{R}\).

- Set M to 0.8 and check that V_a, V_b, V_c, and I_a, I_b, I_c follow the new reference.

- At the end of the experiment, disable the PWM outputs first, and then open the relays by setting the RLY_Close variable to ‘0’.

- Reduce the output of the DC source to 0 V. Double-check in Cockpit that the DC bus is fully discharged.

The screenshot below shows how the workspace could look in the end, while running the test procedure.

To go further…

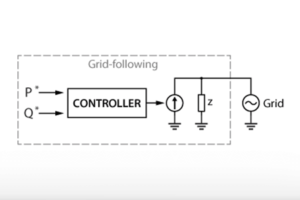

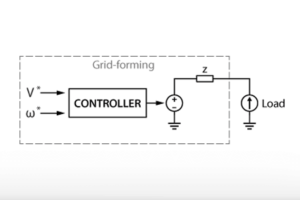

The TPI 8032 is particularly suited for AC microgrid applications. The integrated AC precharge circuit simplifies the grid connection procedure. Active Front End is a basic example showing the principle of grid-connected operations and the precautions of the precharge circuit. It is recommended to read this page first before running the TPI with the grid.

Furthermore, the TPI 8032 can be easily programmed to fit any purpose. More examples of TPI in microgrid applications are available in the knowledge base, such as: