Table of Contents

This note demonstrates the use of imperix control and power products to implement a wind turbine generator control strategy using a sensorless algorithm, tested on a reduced-scale wind turbine testbench.

The note covers the variable-speed sensorless control of the wind turbine generator with MPPT algorithm and the emulation of the wind turbine itself with a motor drive running a physical model of the turbine.

The control code is developed on Simulink, using the ACG SDK library, and experimental results obtained with the imperix power electronics bundle are shown. Please note that imperix offers a ready-to-use motor drive system to develop and test motor control techniques.

Downloads

The Simulink model used in this note can be downloaded under the link below. The same model allows running a PC-based simulation of the whole system and generating run-time code for controlling the motor drives with a B-Box RCP.

Minimum requirements: Imperix ACG SDK ≥3.7 | MATLAB Simulink ≥R2016a | [offline simulation only] Plexim PLECS Blockset (paid license or free demo mode)

General description of the wind turbine generator control testbench

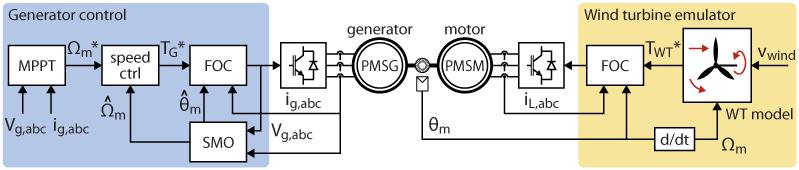

The motor drive testbench used in this application example is meant to test the control of a wind turbine generator. The setup consists of a variable-speed drive of a Permanent Magnet Synchronous Generator (PMSG), coupled with a wind turbine emulator built with a torque-controlled PMSM.

The testbench implements widespread features in small wind energy conversion system (WECS), namely:

- Variable-speed PMSG: has several advantages over traditional generators (SCIG or DFIG) in small- and medium-size systems, including higher overall efficiency, higher reliability, and lower maintenance [1].

- Sensorless control algorithm: is usually preferred over the sensored approach, since it doesn’t rely on position sensors that can impair the system robustness and increase maintenance requirements. Additionally, the well-known limitations of sensorless algorithms at low speeds are not critical in WECS, since they do not operate in the low-speed region [2].

- Fixed-pitch wind turbine: is widely used for small- and medium-scale turbines (< 100 kW) for its superior reliability and excellent efficiency, when used in combination with a variable-speed generator [3].

Wind turbine generator control implementation

Wind turbine emulation

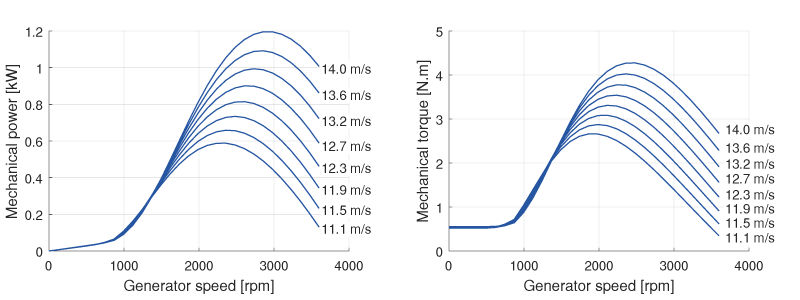

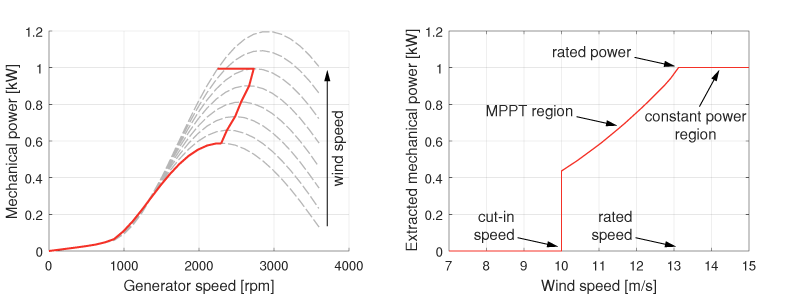

The wind turbine emulator uses the following power and torque curves. These characteristics are derived from the turbine model developed in [5].

The turbine parameters are listed below and have been adapted to match the ratings of the testbench. This allows coupling the wind turbine emulator directly to the PMSG, without the use of a gear box.

| Parameter | Value |

|---|---|

| Maximum mechanical power at rated wind speed | 1 kW |

| Rated rotational speed | 2800 rpm |

| Rated wind speed | 13.2 m/s |

| Blade pitch angle (fixed) | 0 deg |

| Turbine and generator moment of inertia | 0.05 kg.m2 |

The torque applied by the emulator to mimic the behavior of a wind turbine is a combination of two terms:

- The torque generated from the wind blowing against the turbine (computed according to the torque curves above)

- The torque due to the inertia of the turbine, is computed as:

$$T_{inertia} = J_m \frac{d \omega _m}{dt}$$

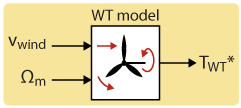

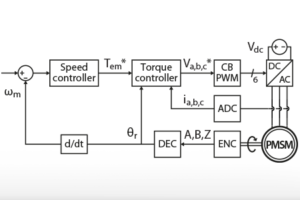

Therefore, the emulator takes as inputs the wind speed (manually entered by the user) and the generator speed (derived from the position and speed measurements), and computes the resulting torque to apply to the generator shaft, as illustrated below.

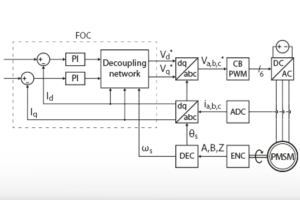

The resulting torque is passed as a reference value to the torque controller of the emulator motor. The motor is then controlled with Field-Oriented Control (TN111), using a shaft encoder for measuring the rotor position.

Wind turbine generator control

Sensorless control

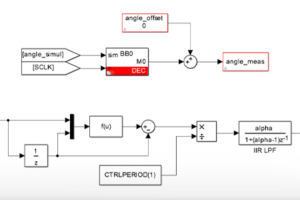

The wind turbine generator is controlled with a sensorless Field-Oriented Control (TN111). The sensorless algorithm uses a Sliding-Mode Observer to estimate the rotor position (TN136). Additionally, the FOC is cascaded with a speed controller (TN114) to be able to adapt the operating point of the generator according to the MPP tracker.

To avoid large estimation errors at low speed, the sensorless algorithm uses an I-f startup method to keep track of the rotor angle during that startup phase. The procedure is adapted from I-f startup for sensorless PMSM control (TN137), which addresses I-f startup in motor mode. In generator mode, the operating principle is similar, except that the machine is rotated by the wind turbine emulator. The stability condition of the I-f startup in generator mode becomes:

$$\frac{d \omega _m^*}{dt} < \cfrac{T_{L,max} + \cfrac{3}{2} p \Psi_{PM}I_{qs}^*}{J_m}$$

Maximum power point tracking

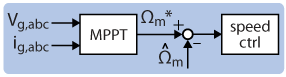

For optimal power extraction from the wind, the operating point of the generator should always be at the maximum of the power curve, for each wind speed. In this note, an MPP tracker uses a simple Perturb & Observe (P&O) algorithm, similar to Maximum Power Point Tracking (MPPT) (TN117). The suitability of a P&O algorithm for wind energy conversion has been addressed in [4] and its main benefit is that it doesn’t require a wind speed measurement or any knowledge of the wind turbine characteristic.

The MPP tracker computes an optimal generator speed that is then used as a reference by the speed controller.

Wind turbine power curve

Wind turbines can’t operate in light-wind conditions, below their cut-in speed. Above that speed, the wind turbine is usually operated along its MPP curve, until the generator reaches its nominal power. Above nominal wind speed, the generator speed is usually decreased to operate at constant power [3].

These different operating modes are illustrated in the power curves below.

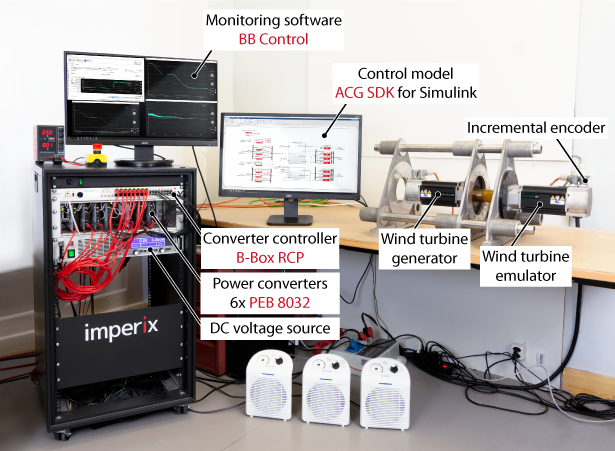

Experimental testbench

The motor testbench is shown below. It contains two back-to-back 1.23 kW PMSMs, driven by two three-phase voltage source inverters. In this configuration, both inverters share the same DC bus. Please refer to PN180 for more information on this topology.

In particular, the following imperix products are featured:

- B-Box RCP controller

- Control implementation using ACG SDK for Simulink

- Converter rack with 6x PEB 8032 IGBT phase-leg module

Experimental results

The experiment was performed with wind speeds ranging from 10 to 14 m/s. At 10 m/s, the torque applied by the wind turbine emulator accelerated the generator. The I-f method was used to track the rotor angle in open-loop until its speed reaches 500 rpm. From there, the control algorithm switches to sensorless FOC, and the MPP tracker brings the system to the top of the power curve. Once the first MPP was reached, the wind speed was progressively increased up to 14 m/s. The MPPT algorithm was updated every 5s with a speed increment of 20 rpm.

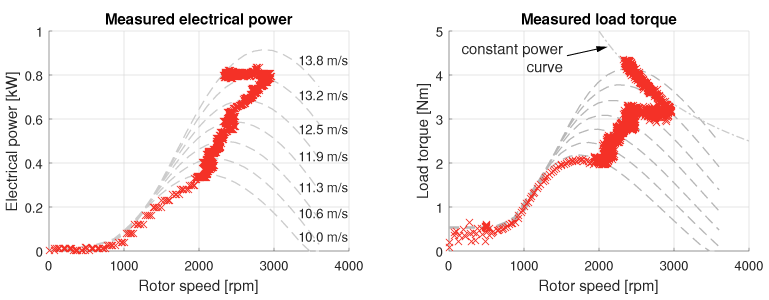

Wind turbine power and torque curves

The figure below shows the measured generator power and torque, superimposed on the wind turbine characteristic curves. The theoretical curves consider an overall efficiency of 80%.

The measured curves match the expected results presented earlier. As expected, the left power curve follows the maxima of the wind turbine curves. Above rated wind speed, the measured power stays constant and the generator speed decreases. As a result, the measured torque increases, following the constant power hyperbola.

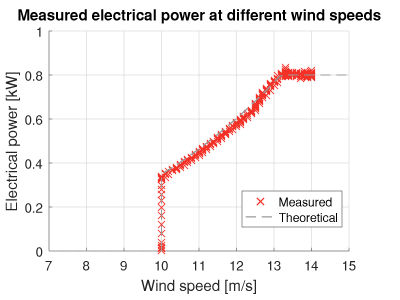

Power vs wind speed

The figure below plots the measured generated electrical power, as a function of the wind speed. The measurements follow the theoretical curve, considering an overall efficiency of the back-to-back system of 80%.

The slight difference between the two curves in the 10 to 12.5 m/s region comes from fast-varying wind speeds that didn’t give sufficient time to the MPPT algorithm to converge before the wind speed changes. On the other hand, speeding up the convergence of the P&O algorithm (i.e. modifying the execution rate and the speed steps) would have led to increased power and torque fluctuations in steady-state, which would eventually lead to increased maintenance requirements. This trade-off between convergence speed and power fluctuation is a drawback of P&O algorithms, and modern WECS usually implement enhanced MPPT algorithms [4].

Academic references

[1] A. Mesemanolis, C. Mademlis and I. Kioskeridis, “Maximum efficiency of a Wind Energy Conversion system with a PM Synchronous Generator,” 7th Mediterranean Conference and Exhibition on Power Generation, Transmission, Distribution and Energy Conversion (MedPower 2010), Agia Napa, 2010.

[2] S. A. Diaz, C. Silva, J. Juliet and H. A. Miranda, “Indirect sensorless speed control of a PMSG for wind application,” 2009 IEEE International Electric Machines and Drives Conference, Miami, FL, 2009.

[3] C. Jiawei, W. Changyun and S. Yongduan, “Power control strategy for variable-speed fixed-pitch wind turbines,” 2014 13th International Conference on Control Automation Robotics & Vision (ICARCV), Singapore, 2014.

[4] C. V. Govinda, S. V. Udhay, C. Rani, Y. Wang and K. Busawon, “A Review on Various MPPT Techniques for Wind Energy Conversion System,” 2018 International Conference on Computation of Power, Energy, Information and Communication (ICCPEIC), Chennai, 2018.

[5] Siegfried Heier, “Grid Integration of Wind Energy Conversion Systems,” John Wiley & Sons Ltd, 1998, ISBN 0-471-97143-X