Table of Contents

This page documents the imperix firmware IP for Xilinx Vivado, which contains the imperix FPGA logic of the imperix controllers, namely the B-Box RCP, the B-Board PRO, the B-Box Micro and the TPI.

The imperix firmware IP enables the user to:

- Exchange data between the application control code running in the CPU (PS) and the logic in the FPGA (PL);

- Drive the PWM output chain, comprised of a dead-time generation system and the hardware protection mechanisms;

- Retrieve ADC conversion results as soon as they are available, directly from within the FPGA;

- Have direct access to physical I/Os pins such as USR, GPI and GPO pins.

Prerequisite to use the imperix firmware IP

- The getting started with FPGA page explains how to use the imperix IP in a Vivado project

- It is required to install Xilinx Vivado to use the imperix firmware IP

- To exchange data with the FPGA and configure the PWM outputs, the necessary drivers are included in ACG SDK (graphical programming) and CPP SDK (C++ programming)

The imperix firmware IP is available for download on the imperix IP download page.

The imperix firmware IP

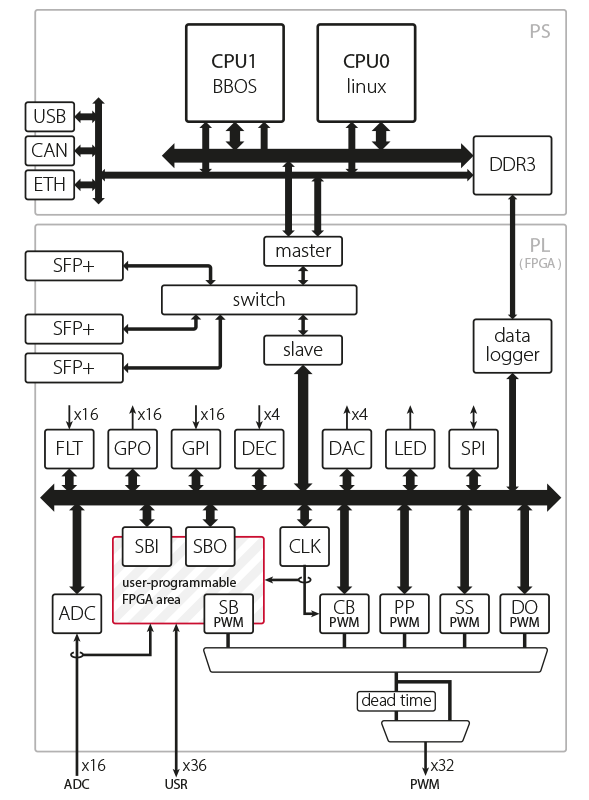

The B-Board is based on a Xilinx Zynq XC7Z030 System-on-Chip which consists of a Processing System area (PS) with two CPU cores and a Programmable Logic (PL) area.

- CPU0: Running on Linux, the first core is responsible for loading the application code, supervising the system execution and managing the data logging.

- CPU1: Running on BBOS (lightweight secured proprietary operating system), the second core executes the application-level control code developed by the user.

- FPGA: The PL contains all the application-specific peripherals.

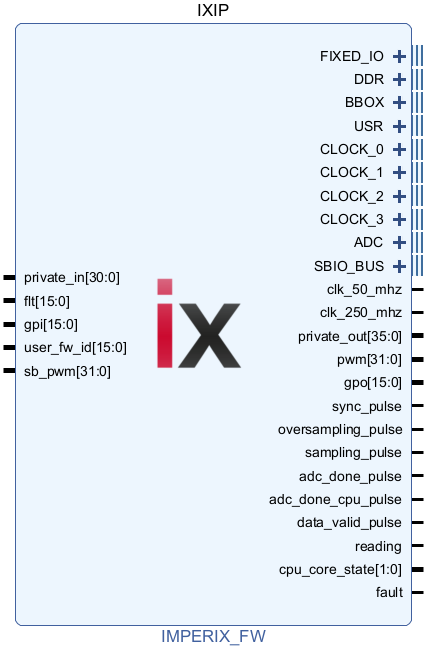

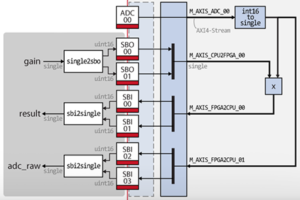

The fixed part of the FPGA firmware containing the pre-implemented peripherals is packaged in the imperix firmware IP. This IP also provides interfaces to the user as illustrated by the user-programmable FPGA area on the image.

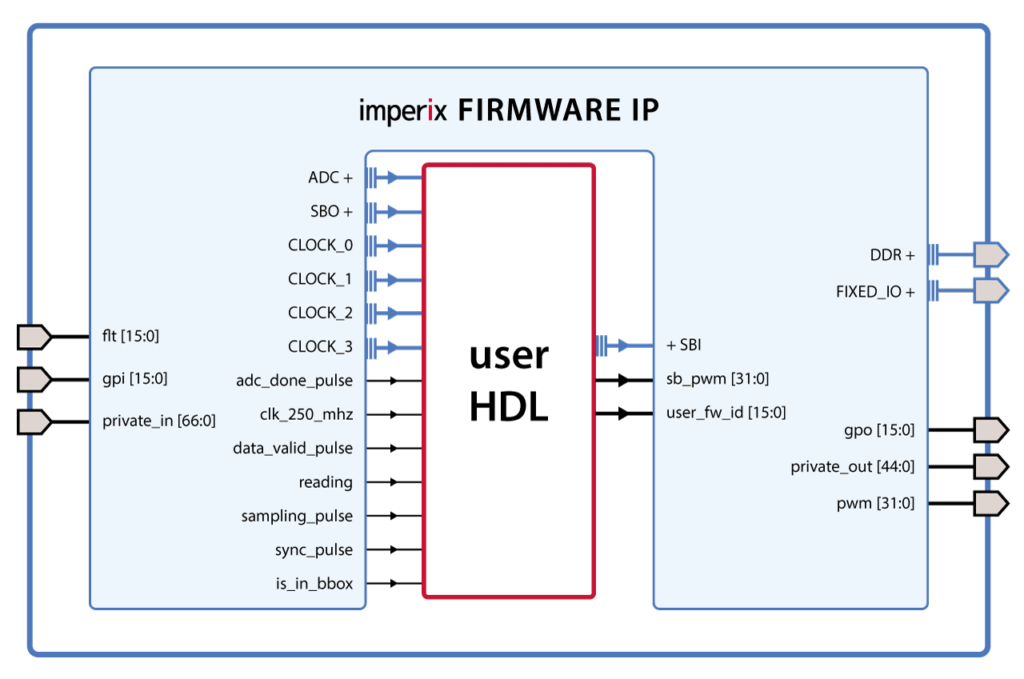

The imperix firmware IP is designed such that it provides interfaces for implementing special user HDL logic in the so-called sandbox. It gives access to some of the I/Os (ADC, PWM,…) as well as ways to exchange data with the CPU (SBI, SBO).

The content of the imperix firmware IP is obfuscated and cannot be either read or edited.

IP port descriptions

This section describes the ports of the imperix firmware IP.

Digital I/Os drivers

These ports drive the physical-digital I/Os of the B-Board. The description of the peripherals driving these ports and the physical location of their I/Os are available in the B-Board datasheet.

| Name | Direction | Clock domain | Description |

|---|---|---|---|

flt[15:0] | input | clk_250_mhz | Fault inputs |

gpi[15:0] | input | clk_250_mhz | General-purpose inputs |

gpo[15:0] | output | clk_250_mhz | General-purpose outputs |

pwm[31:0] | output | clk_250_mhz | Pulse-width modulated outputs |

BBOX[51:0] | tristate input/output | N/A | These pins are used internally in the B-Box RCP. They can be re-purposed when using the B-Board PRO on a custom-made PCB design, as explained in PN201. |

USR[35:0] | tristate input/output | N/A | These 3.3V pins are made available to the user to interface external peripherals, such as an SPI ADC. They are available from the B-Board PRO Eval board and from the B-Box RCP VHDCI connector B. To use these pins, please refer to the Getting Started with FPGA page. |

Private ports

| Name |

|---|

private_in |

private_out |

DDR |

FIXED_IO |

These ports are necessary to communicate with the various components on the B-Board. Modifying these connections could alter the proper behavior of the device.

User interfaces

The user interfaces include data ports and timing signals to exchange data with the CPU, drive PWM outputs, and access ADC value.

| Name | Direction | Clock domain | Description |

|---|---|---|---|

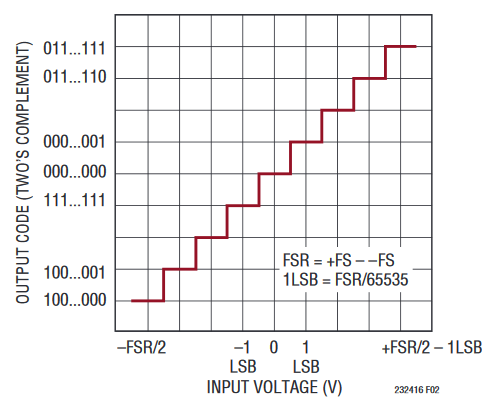

ADC_reg_00[15:00] to ADC_reg_15[15:00] | output | clk_250_mhz | ADC 16-bit result in 2’s complement format. If in a B-Box, registers 00 to 15 hold the results the B-Box (external) ADCs. Otherwise, registers 00 to 07 hold the results of the B-Board on-board ADCs and registers 08 to 15 return zero. |

SBIO_BUS | bidirectional | clk_250_mhz | 16-bit memory-mapped bus allowing the CPU to addressing up to 1024 registers in the FPGA. For more details on SBIO_BUS, see the Getting Started with FPGA page. |

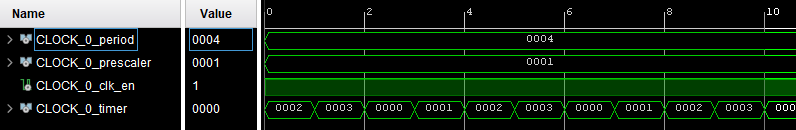

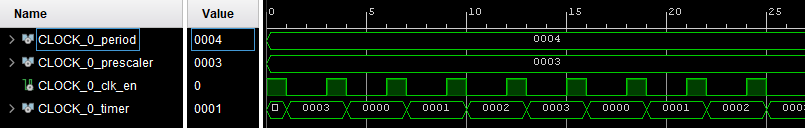

CLOCK_0_period[15:00] to CLOCK_3_period[15:00] | output | clk_250_mhz | Indicates the timer period of the CLOCK. |

CLOCK_0_prescaler[15:00] to CLOCK_3_prescaler[15:00] | output | clk_250_mhz | Indicates the prescaler division value of the CLOCK. |

CLOCK_0_clk_en to CLOCK_3_clk_en | output | clk_250_mhz | Clock enable generated by the prescaler, provides the counting rate of CLOCK_N_timer. CLOCK_N_clk_en is asserted one period out of CLOCK_N_prescaler. |

CLOCK_0_timer[15:00] to CLOCK_3_timer[15:00] | output | clk_250_mhz | Timer counting from 0 to CLOCK_N_period at CLOCK_N_clk_en rate. |

reading | output | clk_250_mhz | Asserted for the duration of the READ phase, signaling that SBI registers are being read and transferred towards the CPU. |

sampling_pulse | output | clk_250_mhz | Asserted for one clock period at each ADC sampling instant. |

sync_pulse | output | clk_250_mhz | Asserted for one clock period at the end of the configuration phase (end of system startup sequence). It may be used as a synchronous reset. In the case where multiple B-Boards (B-Boxes) are connected, this pulse occurs simultaneously in all devices and can be used to synchronize counters. |

user_fw_id[15:00] | input | clk_250_mhz | User firmware identification number. When a customized firmware is loaded, this number is sent to Cockpit and is available from the Target config window in the FPGA bitstream section. It can be used to ensure that the correct firmware has been loaded. |

The images below illustrate the behavior of the CLOCK interfaces.

Understanding the real-time behavior of the firmware

A proper understanding of the system behavior during real-time execution is necessary to correctly develop and integrate custom logic in the B-Board FPGA.

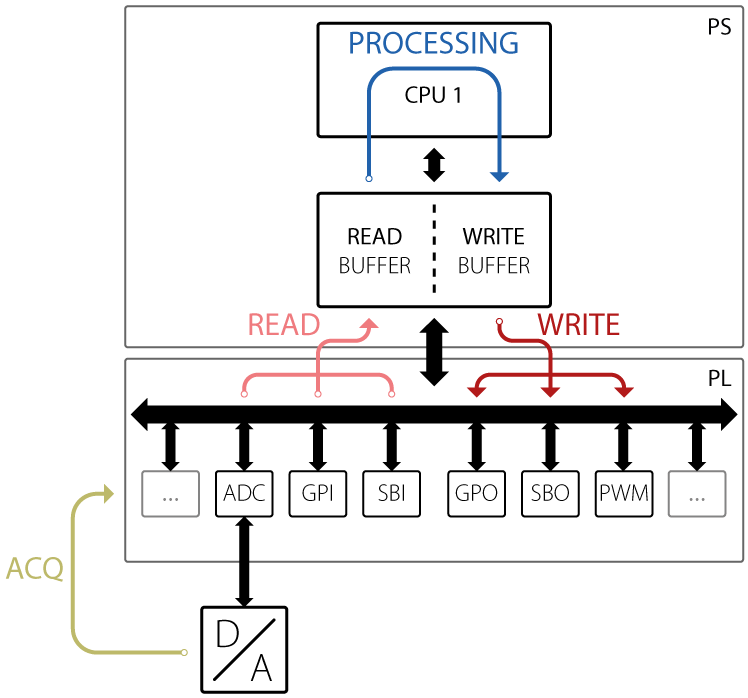

The four phases of a control cycle

The next figure is a simplified representation of the elements involved in the real-time execution of the control algorithm on an imperix controller. It shows the four phases constituting a control cycle, which are:

- ACQ: Analog-to-digital conversion (physical chips) and results acquisition (transfer to FPGA);

- READ: Real-time DMA read, FPGA data flagged as real-time are sent to the CPU read buffer;

- PROCESSING: Execution by the CPU of the main control task, processing the user control code. At the beginning of this phase, the CPU read buffer is read. At the end, the CPU write buffer is updated.

- WRITE: Real-time DMA write, data flagged as real-time are transferred from the CPU write buffer to the FPGA peripherals (across the network of multiple B-Boards if needed).

To learn more about the various delays involved when running an imperix digital controller please read the discrete control delay identification page.

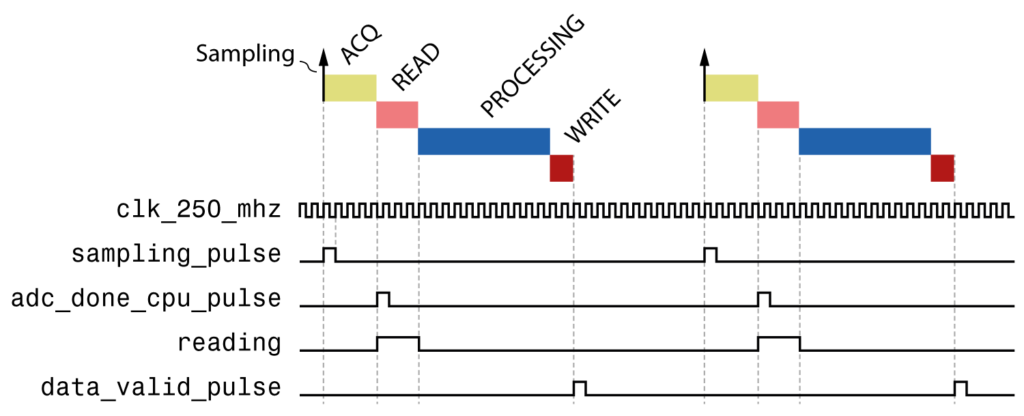

The imperix firmware IP provide timing information, as shown in the next figure. The _pulse signals are asserted only for one period of clk_250_mhz.

- The

sampling_pulsesignal indicates the ADC sampling instant and the start of the ACQ phase. - The

adc_done_pulsesignal indicates that the ACQ phases finished and new ADC values are available in theADCregisters. - The

readingsignal indicates the start of the READ phase whenSBIregisters flagged as real-time are sent to the CPU memory. - At the end of the WRITE phase

data_valid_pulseis asserted notifying that new data is available in the real-timeSBOregisters.

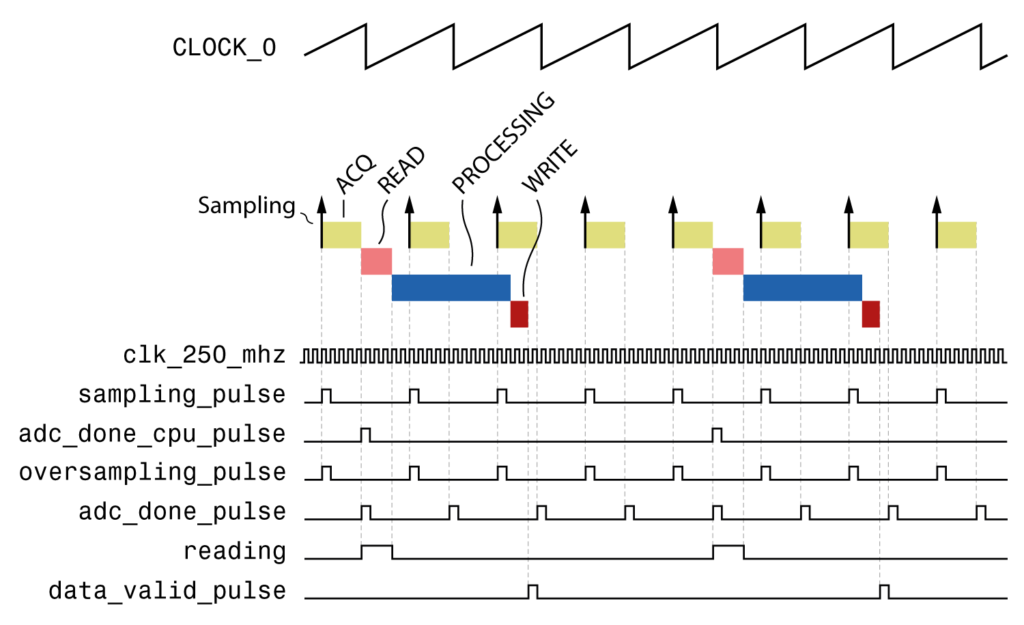

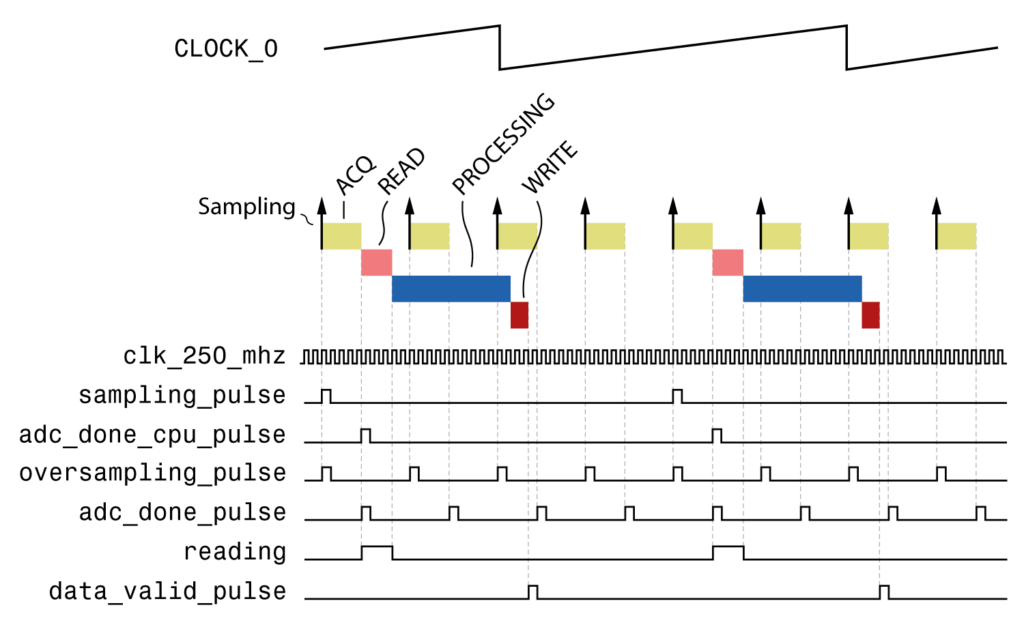

Executing the FPGA-based algorithm faster than the CPU

The ADC sampling is always linked to CLOCK_0 and can be configured using the Configuration block. The control algorithm is generally executed after each new ADC sample, so for the FPGA-based algorithm to run faster the sampling rate must be increased. It may be done by:

- Increasing the frequency of CLOCK_0 (recommended)

- Setting an SCLK multiplier factor (legacy)

Increasing the frequency of CLOCK_0

Increasing the frequency of CLOCK_0 is the recommended method to increase the ADC sampling rate. Because the CPU is usually not able to run as fast as the FPGA, using the CPU postscaler can be used to reduce the CPU control task rate. The CPU postscaler can be configured in the Configuration block.

Setting an SCLK multiplier factor

Alternatively, an SCLK multiplier may be set as illustrated below.

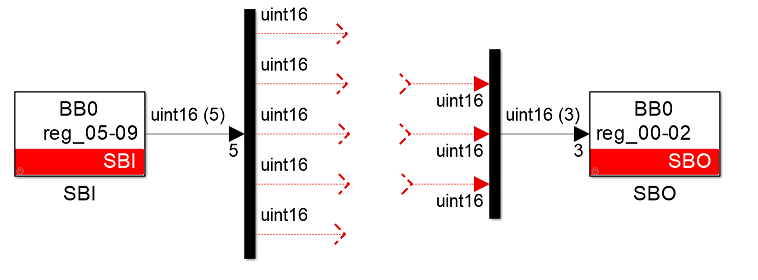

Exchanging data between the CPU and the FPGA

The 16-bit Output towards the SandBox (SBI) and Input from the SandBox (SBO) registers allow data exchange between the user control code in the CPU and the user logic in the FPGA. These registers can be read/written using their respective blocks (SBO and SBI).

The getting started with FPGA development page goes into further details on how to exchange data between the CPU and the FPGA through a step-by-step example.

Configuration phase

The configuration phase occurs only once at the system startup and aims to initiate FPGA-based peripherals and configure the real-time data traffic, possibly across the control network. During this phase, interrupts and PWM operations are not yet active.

With the ACG SDK, sBO registers that are only written once are called configuration registers, opposing to real-time registers. The user selects which registers are set as configuration registers from the “Registers” tab of the SBO block and then sets up their values from the “Configuration reg. values” tab. When using C++ SDK, the SBI/SBO registers can be read/written during the configuration phase by using Sbi_ReadDirectly or Sbo_WriteDirectly in the UserInit() function.

Sbi_ReadDirectly and Sbo_WriteDirectly functions infer immediate data transfers, which are rather time-consuming performance-wise and, therefore, cannot be used during real-time execution.Real-time execution

Configuring a SBI or SBO register as a real-time register indicates that the value of this register is to be transferred at each control task execution. Configuring a register as real-time is done by using the C++ function Sbi_ConfigureAsRealTime or Sbo_ConfigureAsRealTime.

In Simulink, real-time registers are clearly distinguished from configuration registers. They take their run-time values from the block inputs.

Before entering the control interrupt, the data that have previously been configured as real-time are retrieved from the FPGA peripherals and placed into the CPU read buffer (READ phase). As such, they can readily be used from inside the control interrupt using Sbi_Read.

Reciprocally, using the Sbo_Write function inside the control interrupt stores data into the write buffer, waiting to be sent back to the FPGA once the interrupt is completed (WRITE phase).

In Simulink real-time data can be easily manipulated using signal wires.

Retrieving ADC conversion results

Inside the FPGA, ADC results are available from the ADC interface of the firmware IP. The port sampling_pulse indicates the start of an ADC conversion and adc_done_pulse indicates that the results are available in the ADC interface. The conversion 16-bit results are in 2’s complement format.

– The datasheets of B-Box RCP or B-Box Micro for laboratory devices.

– The datasheet of the B-Board PRO or PN201 for embedded systems.

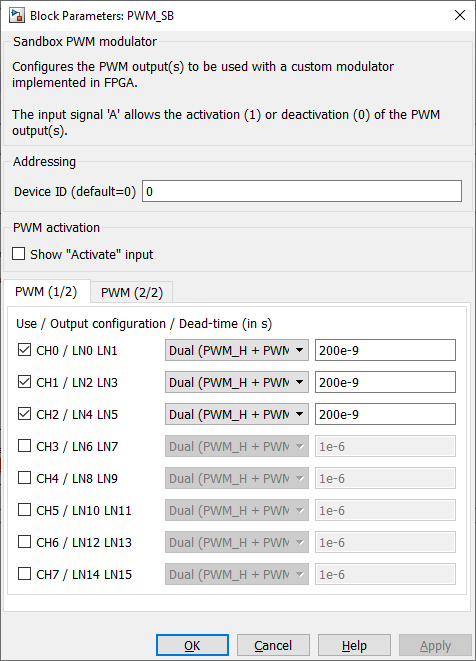

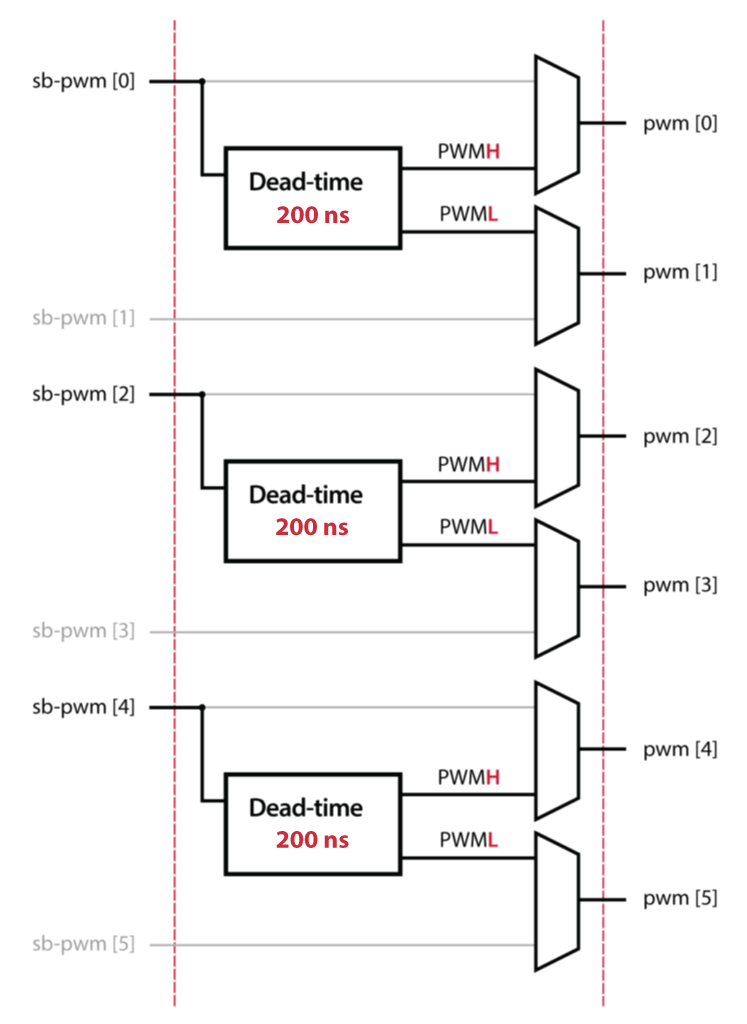

Driving PWM outputs

On the firmware IP, the sb_pwm[31:0] port provides access to the same PWM output chain as that used by other modulators (CB-PWM, PP-PWM, DO-PWM and SS-PWM). This allows the user to generate complementary signals with dead-time, use the standard activate and deactivate functions and rely on the protection mechanism that blocks PWM outputs when a fault is detected. A use example is available on the page Custom PWM modulator implementation in FPGA.

The PWM chain can be configured using the Sandbox-PWM (SB-PWM) block. An example is shown below.

Each bit of the sb_pwm[31:0] IP port corresponds to a PWM lane.

sb_pwm[0]: lane #0sb_pwm[1]: lane #1sb_pwm[2]: lane #2- etc.

sb_pwm input (sb_pwm[0], sb_pwm[2], sb_pwm[4], etc.). An example of such a configuration is available in TN120.pwm port, as this would bypass the enable/disable mechanism! Instead, the SB-PWM port is meant to provide proper access to PWM outputs, which should be used in all cases.On B-Box RCP, this is only relatively sensitive as hardware protections exist. However, on B-Board PRO, this is critical since this mechanism also handles the fault management !

– The datasheets of B-Box RCP or B-Box Micro for laboratory devices.

– The datasheet of the B-Board PRO or PN201 for embedded systems.

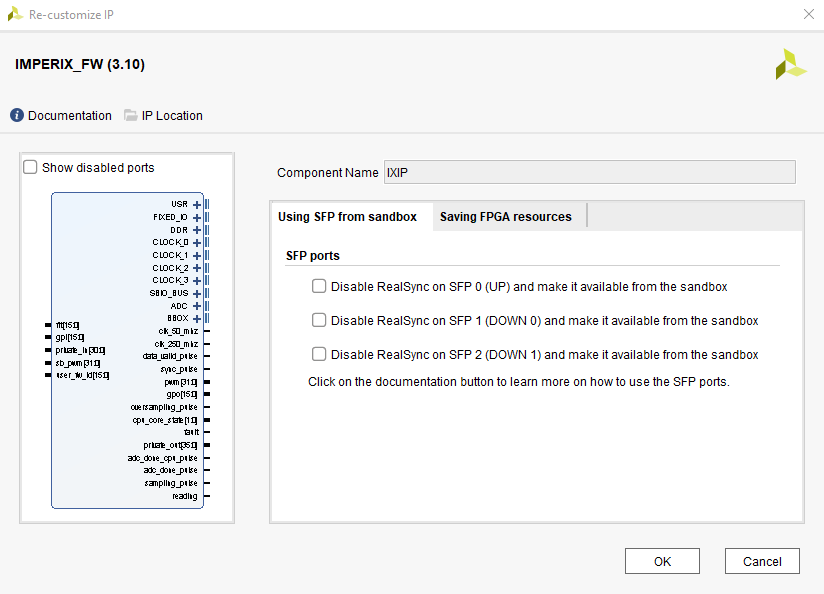

IP configuration

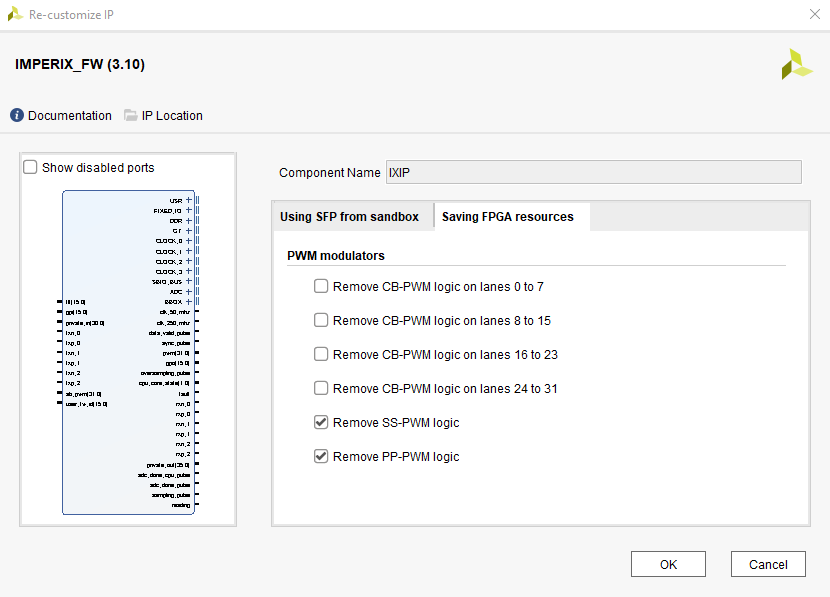

Since version 3.10, the imperix IP is configurable:

- The SFP port can be repurposed by the user, to implement custom communication between devices using the Aurora protocol. An example of SFP port repurposing is available on the page Example of FPGA-based Aurora 8B/10B communication.

- Unused PWM modulators (CB-PWM, SS-PWM or PP-PWM) can be removed, to save up FPGA resources.

Download

The source files are now available on the imperix IP download page.